MajD

New member

We'll see how they hold up I only have a few thousand miles on them. What was your experience?Those ball joint deletes are fucking trash. Absolutely no conservative approach to safety with those things. You do you though.

We'll see how they hold up I only have a few thousand miles on them. What was your experience?Those ball joint deletes are fucking trash. Absolutely no conservative approach to safety with those things. You do you though.

Umm, unless I'm missing something, WJCO was trying to be funny by laughing the way the comment he quoted could sound sexual. I think that's a far cry from "everyone" gang jumping on you. As for me, all I did was share my LIMTED experience. I never said that had machinists in my family or that I was an engineer or spent any time googling the subject. If my comment somehow equals "everyone" gang jumping on you, I really do apologize as it certainly was not my intent to jump on you or pretend to be "everyone". Like you, I was just trying to be helpful by sharing a different perspective and didn't mean to get you so offended.Look, use anti-seize or don't use anti-seize it probably won't make a difference if you get your press right. I'm not in a dick measuring competition with any of you and I'm not going to die on this hill. This is what I hate about forums, you try to be helpful and give an opinion and the gang jumps in on you. I have some machinists in my family, and we've had this discussion a number of times. Any press fittings will eventually wear out. That is a fact, and you don't have to have a degree in engineering to google search that. The likelihood of it happening over lifespan of an axle would depend on a lot of factors. If you get your presses right the tolerances will allow that axle to last for a long time and will likely not be the determinate factor in that vehicle ending up in the recycle pile. Press enough fittings into it over time and or gouge it doing it incorrectly and the metal will wear improperly causing premature failure. Has it happened to you and you do it all of the time? No? well maybe you know what you're doing and you buy good quality products. Have press fittings failed? yes they have. With computerized machining these days Dana is getting tolerances closer to .001 to .002 so they are incredibly tight. Is there a magic number of how many times it takes to wear it out? The answer is no because there is to many variables. My entire point is to take the conservative approach for safety by reducing the likelihood of premature failure by not wearing it out to begin with. You do you Eddie/WJCO

www.wayalife.com

www.wayalife.com

It's all good Eddie I'm pissed off at the world today for some reason, sorry about that. Anyways that severed bolt looks no bueno on the AI BJDs. It looks like a failure in the casting process, it shouldn't have severed at 45lbs. The final torque spec is 65lbs once the weight of the vehicle is on the ground. I'm also running Reid knuckles just like that photo. My initial observation is the same as Disciple Off Road that the Nylon nut might come loose, the bolts need to be another 1-2 mm longer to fully capture the nylon thread on the nut so I'm worried about retention long term. I've would have gone with a standard Castle Nut so I'm not sure on the design choice there and reasoning for that. Either way they are installed on my JLUR so I'll keep an eye on them and post a longer term more objective review. I have a Moab trip planned in June so they'll be put through some serious off-road paces, and I'll report back my findings. Not a "fanboy" but I'm also not going to be quick to call them out as garbage based on some internet posts and one damning install photo. The drivability so far has been great and I'm not hearing any steering noises yet. It's been hard finding objective reviews on these so far people who have been running them long term.Umm, unless I'm missing something, WJCO was trying to be funny by laughing the way the comment he quoted could sound sexual. I think that's a far cry from "everyone" gang jumping on you. As for me, all I did was share my LIMTED experience. I never said that had machinists in my family or that I was an engineer or spent any time googling the subject. If my comment somehow equals "everyone" gang jumping on you, I really do apologize as it certainly was not my intent to jump on you or pretend to be "everyone". Like you, I was just trying to be helpful by sharing a different perspective and didn't mean to get you so offended.

As far as ball joint deletes go, here's a thread that you should check out,

In The Shop - Disciple Off Road

Good adhesion of any adhesive comes from proper prep. I think you hit it on the head here. 3M VHB tape isn't just a peel and stick operation, it's a process, and the better you follow the process the better your results will be.www.wayalife.com

That's not my opinion, that is what a reputable shop has experienced.

Peace

Too late for Driver Side.Already installed but will use that trick on the other side. But I got it pretty clean with scotchbrite pad and break kleen. Adding that to my bag of tricks though, Thanks!

View attachment 389309

After asking here. @wayoflife said that he was disappointed in the RCV product, and that the chromoly axle assemblies from Spicer were just as good for less money. Wayalife saving me money again so I bought $50 worth of stickers.As long as you don't have CV boots on your axle shafts, there should be nothing to hit if pointing straight back.

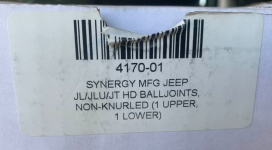

Eddie's came with the kit as you'll see in the video below. They were in the bag on his bench and you'll see them installed around 17:00 mark. I would first make damn sure you have the right ball joints. Then run down to the hardware store and pick up a Grade 8 washer.FUN FACT, In the Synergy HD BJ Packing list, it mentions 1 Flat Washer, Grade 8, 9/16" SAE. HOWEVER, In none of the packages do these washers exist. I looked in all the spare sets I ordered as well. In Synergy's instructions, they mention using this washer between the LWR BJ and the Castle Nut. Do we think Synergy has outdated instructions and doesn't ship the washer anymore because they don't want us using it? Or is this just a batch of BJ's missing the washer? Do I go buy washers? Do I postpone my project till Monday so I can ask Synergy? What would you do?

Good thinking, but I opened the other box and it seems that this is some sort of quality control or batch number. They even label the boxes with the name of the guy who packed them.WJCO bringing up the video got me to watch it again, in the video, the ball joints are marked with "C21", yours are marked with "H21".

You may want to verify you received the correct ball joints.

Seems more like that is a batch number. I opened another box of them, I bought 4 sets, they are various numbers yet all boxes indicated they are for JT.WJCO bringing up the video got me to watch it again, in the video, the ball joints are marked with "C21", yours are marked with "H21".

You may want to verify you received the correct ball joints.