Colorado4x4

Active Member

Greetings,

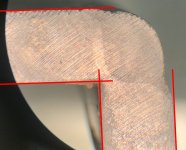

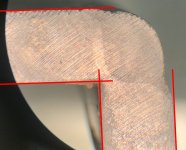

I think we have some experienced welders here. I am trying to get better with my welds. A buddy of mine has a Lexus GX and he ordered a weld-together bumper from some offroad shop and I am going to weld it up for him. It is 3/16" plate steel that is CNC bent & cut so it should be a pretty easy fit up and shouldn't be too bad of a job to put together. I'm running a Hobart Handler 140 with 0.030" solid wire and 75/25 gas. Most of the bumper is outside open corner joints and inside fillet welds. I ran a couple beads on some coupons and did a cut and etch to check penetration on them and I thought I had a perfect fit up with no open gap. I was puzzled by the results a little bit because it looks like the fit up overlapped a little bit, or did the top plate pull in as I was welding?

Is this good enough penetration? I might just go with a straight pull or push instead of whip and pause. Any thoughts?

I think we have some experienced welders here. I am trying to get better with my welds. A buddy of mine has a Lexus GX and he ordered a weld-together bumper from some offroad shop and I am going to weld it up for him. It is 3/16" plate steel that is CNC bent & cut so it should be a pretty easy fit up and shouldn't be too bad of a job to put together. I'm running a Hobart Handler 140 with 0.030" solid wire and 75/25 gas. Most of the bumper is outside open corner joints and inside fillet welds. I ran a couple beads on some coupons and did a cut and etch to check penetration on them and I thought I had a perfect fit up with no open gap. I was puzzled by the results a little bit because it looks like the fit up overlapped a little bit, or did the top plate pull in as I was welding?

Is this good enough penetration? I might just go with a straight pull or push instead of whip and pause. Any thoughts?

Last edited: