GCM 2

New member

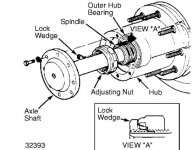

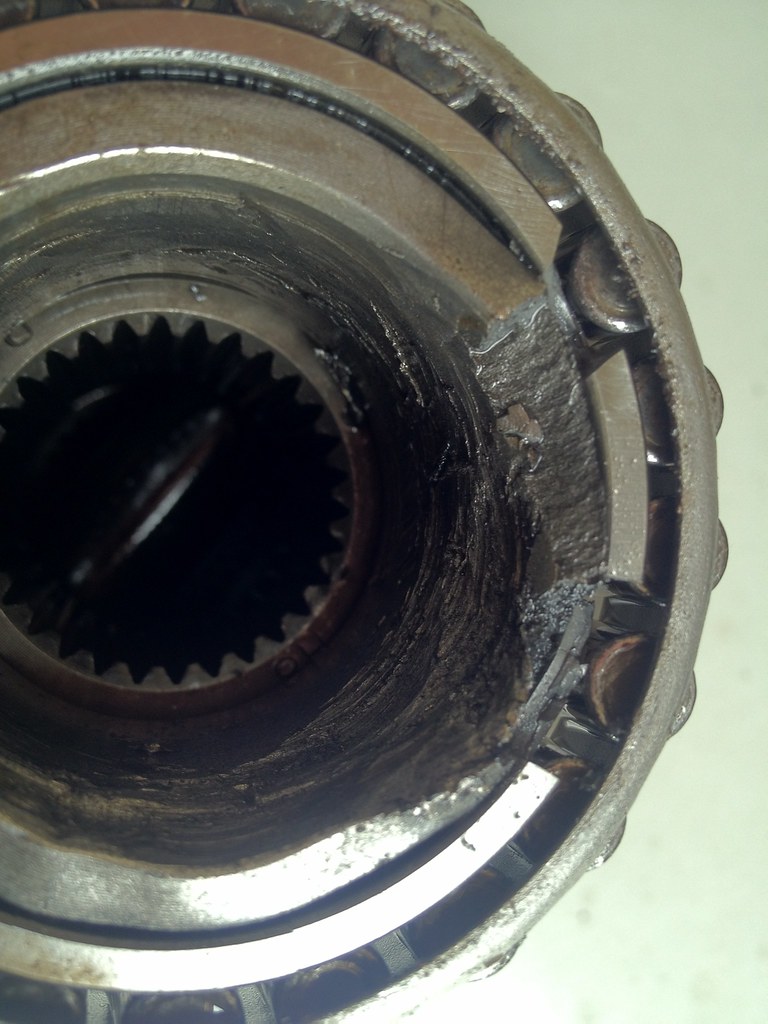

Like a handful of JK owners running ProRock 60 full float axles, I often get asked the "what is/why run full float axles......."question. Well, Offroad Evolution just posted this photo on their Facebook page of probably the best visual explanation of what is a "Full Float Axle". From this visual, you can see the tire/wheel is still bolted to the spindle on the outer axle housing tube, yet the the drive axle is almost completely pulled from the axle housing.

Some benefits of the full float axle are:

-all the weight of the vehicle is supported by the axle tube/housing. The axle shaft bears no load carrying capacity. Axle housing load capacities are significantly greater on full floats when compared to semi-float axles. Very important when running larger than 37"s

-the axle shaft serves only to transfer rotational power to wheels, nothing else.

-if you snap an axle, simply pull the broken shaft, and because you still have a functioning rolling tire on that corner you can continue(albeit carefully) with only one rear wheel being driven. If you carry spare axle shafts, simply replace with a new one on the trail!

-axle shafts are not C-clip'd into the differential carrier, so no need to break the diff cover seal if the axle should break.

-this is old school and not done much anymore, but you can also add locking wheel hubs to vehicles with rear full float axles. The purpose for this if the vehicle normally gets towed to the trail or behind motor homes. Simply unlock hubs and this allows for free spinning rear wheels while being towed, no need to remove driveshafts to isolate the drivetrain.

-

Some benefits of the full float axle are:

-all the weight of the vehicle is supported by the axle tube/housing. The axle shaft bears no load carrying capacity. Axle housing load capacities are significantly greater on full floats when compared to semi-float axles. Very important when running larger than 37"s

-the axle shaft serves only to transfer rotational power to wheels, nothing else.

-if you snap an axle, simply pull the broken shaft, and because you still have a functioning rolling tire on that corner you can continue(albeit carefully) with only one rear wheel being driven. If you carry spare axle shafts, simply replace with a new one on the trail!

-axle shafts are not C-clip'd into the differential carrier, so no need to break the diff cover seal if the axle should break.

-this is old school and not done much anymore, but you can also add locking wheel hubs to vehicles with rear full float axles. The purpose for this if the vehicle normally gets towed to the trail or behind motor homes. Simply unlock hubs and this allows for free spinning rear wheels while being towed, no need to remove driveshafts to isolate the drivetrain.

-

Attachments

Last edited: