You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Uncharted build

- Thread starter IceKnight

- Start date

IceKnight

New member

Got the parking brake lines installed.

I am using the XJ rear parking brake lines for my 8.8, they fit perfectly.

This was the week I got my rear bumper back from paint and the rocker guards. I was going to wait to install them until after I painted it but have back burnered the painting thing for now.

And my LED's show'd up as well. Ill be mounting the light bar on a bracket that I'm going to build that will sit right above the roller fairlead directly in front of the winch. The 2" lights are a 60 degree pattern and the light bar has 8 and 120 degree patterns. I'm hoping that with these three patterns I get nice full coverage as well as being apocalypticly bright.

I am using the XJ rear parking brake lines for my 8.8, they fit perfectly.

This was the week I got my rear bumper back from paint and the rocker guards. I was going to wait to install them until after I painted it but have back burnered the painting thing for now.

And my LED's show'd up as well. Ill be mounting the light bar on a bracket that I'm going to build that will sit right above the roller fairlead directly in front of the winch. The 2" lights are a 60 degree pattern and the light bar has 8 and 120 degree patterns. I'm hoping that with these three patterns I get nice full coverage as well as being apocalypticly bright.

IceKnight

New member

I had a chance to visit the local Stealership and pick up a new flag nut for the front lower track bar. $17 bucks for a nut...wish I had my welder at the house. If anyone needs the part number here is a pic of it.

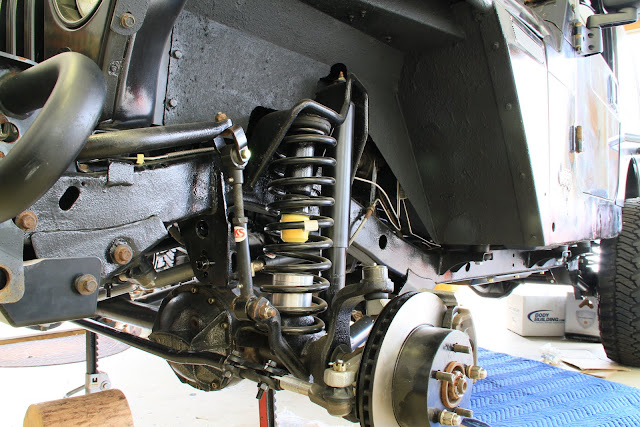

Got my alignment all squared away and my steering wheel lined up straight. My steering wheel has never been straight since I have owned my Jeep. On a side note, while getting things set up for my alignment I realized I never torqued down my axle shafts. I should have known because I have been paint marking everything as I finish torque and there was no markings. Oh well fixed now.

I am hoping to remove a little of my bump stop extensions as well for more up travel but I need to flex everything out and see if anything hits.

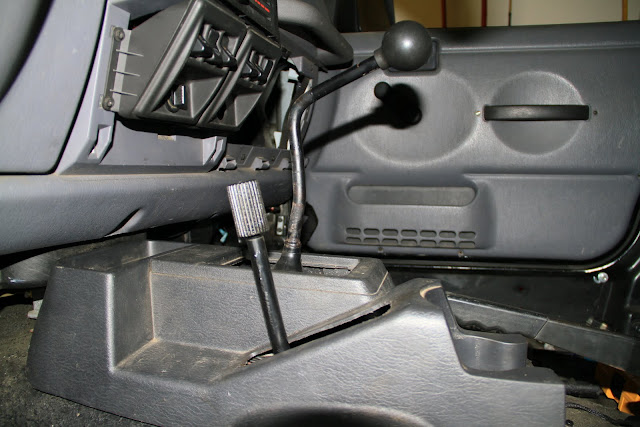

I also got my transfer case shifter and custom knob completely installed and tossed the console in to make sure everything fit as it should. Any guess what the knob is from?

I also got my front drive shaft installed...what a pain to do by yourself.

Got my alignment all squared away and my steering wheel lined up straight. My steering wheel has never been straight since I have owned my Jeep. On a side note, while getting things set up for my alignment I realized I never torqued down my axle shafts. I should have known because I have been paint marking everything as I finish torque and there was no markings. Oh well fixed now.

I am hoping to remove a little of my bump stop extensions as well for more up travel but I need to flex everything out and see if anything hits.

I also got my transfer case shifter and custom knob completely installed and tossed the console in to make sure everything fit as it should. Any guess what the knob is from?

I also got my front drive shaft installed...what a pain to do by yourself.

IceKnight

New member

I finished wiring my 2" LED spot lights, which are far and away brighter then my head lights. Looks like LED headlights are now back on the menu. I also plugged in my light bar just to see how it looked....WOW I thought the 2" lights where bright. I need to build the mount for this over the next week or two as well as get my winch so I can properly measure things to make sure it'll fit right.

I got my horns wired up, just some simple dual Hella horns. These things are so loud that I can feel them in my steering wheel and floor boards lol. Not exactly what I was looking for but it'll pass inspection.

Installed my rockers and tossed in the bedrug carpet I got in last week. Which seems to fit quite well, I'll have a little trimming to do but nothing to crazy. Not bad for just over $150.

And last but not least, went to bleed the brakes and realized I installed the calipers with the bleeder side down....looking like a caliper flip is in the books for later on this week.

After all the building things are measuring up like this.

Front Axle - 11 5/8"

Rear Axle - 10 1/2"

Trans Skid - 18"

Gas Skid - 17 3/4"

Rockers - 24"

Frame measurements

Front - 25"

Middle - 20"

Rear - 23 1/2"

So before I took it to have everything inspected I was still having issues with a check engine light.

I ended up ordering and replacing the TPS, IAC, MAP and up stream O2 sensors. I figured I have replaced everything else on this thing why not have all of those new as well. Which solved nothing lol.

I ended up going to have it inspected so I could at least get it registered again. It failed because of the computer was not able to communicate with the Jeep. So after that I took some time to check all the main connection points and everything was perfectly clean and hooked up correctly. I started looking everywhere for a bad or cut wire and I found two. The two grounds right above the intake manifold up against the fire wall on the drivers side. I hooked those up and what'da know the OBDII started reading perfectly. I still have the engine light but now I could read the code. Which was for the battery temp sensor. Which I order up and replaced. I finally got my inspection done again and passed with fly colors.

I still have some other things to do, paint touch up, buy a winch and build my led light bar bracket. But other than that things a almost 100%, well as 100% as any Jeep project can be. Just need to finish the engine break-in change the oil and get it out on the trail.

I got my horns wired up, just some simple dual Hella horns. These things are so loud that I can feel them in my steering wheel and floor boards lol. Not exactly what I was looking for but it'll pass inspection.

Installed my rockers and tossed in the bedrug carpet I got in last week. Which seems to fit quite well, I'll have a little trimming to do but nothing to crazy. Not bad for just over $150.

And last but not least, went to bleed the brakes and realized I installed the calipers with the bleeder side down....looking like a caliper flip is in the books for later on this week.

After all the building things are measuring up like this.

Front Axle - 11 5/8"

Rear Axle - 10 1/2"

Trans Skid - 18"

Gas Skid - 17 3/4"

Rockers - 24"

Frame measurements

Front - 25"

Middle - 20"

Rear - 23 1/2"

So before I took it to have everything inspected I was still having issues with a check engine light.

I ended up ordering and replacing the TPS, IAC, MAP and up stream O2 sensors. I figured I have replaced everything else on this thing why not have all of those new as well. Which solved nothing lol.

I ended up going to have it inspected so I could at least get it registered again. It failed because of the computer was not able to communicate with the Jeep. So after that I took some time to check all the main connection points and everything was perfectly clean and hooked up correctly. I started looking everywhere for a bad or cut wire and I found two. The two grounds right above the intake manifold up against the fire wall on the drivers side. I hooked those up and what'da know the OBDII started reading perfectly. I still have the engine light but now I could read the code. Which was for the battery temp sensor. Which I order up and replaced. I finally got my inspection done again and passed with fly colors.

I still have some other things to do, paint touch up, buy a winch and build my led light bar bracket. But other than that things a almost 100%, well as 100% as any Jeep project can be. Just need to finish the engine break-in change the oil and get it out on the trail.

IceKnight

New member

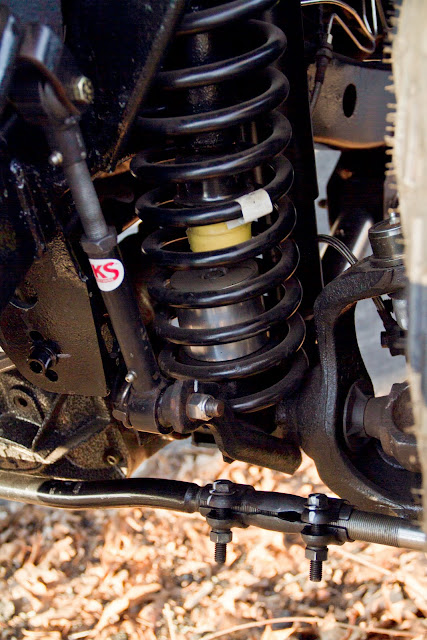

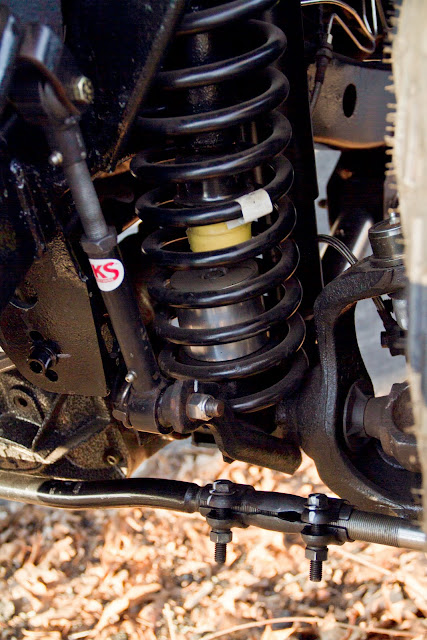

So I took a few flexing shots and poser shots.

For the flex shots I left the front sway bar connected which didn't really allow for a huge amount of flex. I'm going to remove them at some point and recheck

I also think I need to remove a little bumpstop to allow for more travel I still have plenty of room on my shock to use up (about 5 inches) but I really have to fully cycle my suspension a bunch before I start pulling it out I guess. I took a lot of time measuring before everything went in so I don't want to waste time if its keeping everything safe right now.

For the flex shots I left the front sway bar connected which didn't really allow for a huge amount of flex. I'm going to remove them at some point and recheck

I also think I need to remove a little bumpstop to allow for more travel I still have plenty of room on my shock to use up (about 5 inches) but I really have to fully cycle my suspension a bunch before I start pulling it out I guess. I took a lot of time measuring before everything went in so I don't want to waste time if its keeping everything safe right now.

TDIpowered

New member

Awesome build man

IceKnight

New member

Haven't really done much of anything to the Jeep over the past few weeks, heck I haven't even had time to take it wheeling now that the break in miles are done and oil has been swapped.

One thing I can say is that spinning 35's (which is not a regular thing because of the cost) is really fun.

Another thing is that the LSD in my 8.8 doesn't really do a thing. I half expected it, but seeing as I was going to rebuild the clutch pack in it anyway I figured I may as well put in the racing clutches to maybe get a little more grab, well not so much. Just didn't have the money at the time to get a locker. Now that my winch is inbound, I can start looking for a locker.

I took the sway bar discos off and flexed a little more, and along the way found some clearance issues with tire turn. Looking like I'm going to need another washer in the steering stop to keep the tire off the frame and steering gear box bolts. oh and I have some bump stop adjusting to do.

One thing I can say is that spinning 35's (which is not a regular thing because of the cost) is really fun.

Another thing is that the LSD in my 8.8 doesn't really do a thing. I half expected it, but seeing as I was going to rebuild the clutch pack in it anyway I figured I may as well put in the racing clutches to maybe get a little more grab, well not so much. Just didn't have the money at the time to get a locker. Now that my winch is inbound, I can start looking for a locker.

I took the sway bar discos off and flexed a little more, and along the way found some clearance issues with tire turn. Looking like I'm going to need another washer in the steering stop to keep the tire off the frame and steering gear box bolts. oh and I have some bump stop adjusting to do.

IceKnight

New member

So Friday night I finally got out on the trail with my brother and he got this short video with his cell.

Made it about half way on the trail and we came up to the crest of a small hill my clutch line went...and by went of course I mean it exploded. Then ensued the long task of getting the Jeep out of the woods which was empty of tools (aside from the driver for going wheeling with none). After heading back to the house on foot minutes before it got dark, then go back and clearing the trail of tree debris that looked like a hurricane had torn through the woods and getting things running finally got it out and home.

I ended up buying a new line from Advanced Adapters. It's a stainless braided hose, no more brittle plastic. Used this line before on another jeep project and haven't had a problem.

I must say though, the one that broke was my original from 1998, so all and all a 16 year old part that lasted through all that abuse... not to shabby.

One more thing that must be said...the wife did tell me during the build to just replace it with a new one and in all my brilliance I was all, "na if it ain't broke don't fix it"...yeah well it broke... go me.

If I can get my camera in these tight spots I'll do a quick write up.

Made it about half way on the trail and we came up to the crest of a small hill my clutch line went...and by went of course I mean it exploded. Then ensued the long task of getting the Jeep out of the woods which was empty of tools (aside from the driver for going wheeling with none). After heading back to the house on foot minutes before it got dark, then go back and clearing the trail of tree debris that looked like a hurricane had torn through the woods and getting things running finally got it out and home.

I ended up buying a new line from Advanced Adapters. It's a stainless braided hose, no more brittle plastic. Used this line before on another jeep project and haven't had a problem.

I must say though, the one that broke was my original from 1998, so all and all a 16 year old part that lasted through all that abuse... not to shabby.

One more thing that must be said...the wife did tell me during the build to just replace it with a new one and in all my brilliance I was all, "na if it ain't broke don't fix it"...yeah well it broke... go me.

If I can get my camera in these tight spots I'll do a quick write up.

Last edited:

darkknight1999

Member

So Friday night I finally got out on the trail with my brother and he got this short video with his cell.

Made it about half way on the trail and we came up to the crest of a small hill my clutch line went...and by went of course I mean it exploded. Then ensued the long task of getting the Jeep out of the woods which was empty of tools (aside from the driver for going wheeling with none). After heading back to the house on foot minutes before it got dark, then go back and clearing the trail of tree debris that looked like a hurricane had torn through the woods and getting things running finally got it out and home.

I ended up buying a new line from Advanced Adapters. It's a stainless braided hose, no more brittle plastic. Used this line before on another jeep project and haven't had a problem.

I must say though, the one that broke was my original from 1998, so all and all a 16 year old part that lasted through all that abuse... not to shabby.

One more thing that must be said...the wife did tell me during the build to just replace it with a new one and in all my brilliance I was all, "na if it ain't broke don't fix it"...yeah well it broke... go me.

If I can get my camera in these tight spots I'll do a quick write up.

LOL That was pretty awesome though...

Oh and next time we're going to bring the GoPro

Rharvey160

New member

Awesome build. If I had the skills neccessary I'd love to do such a project.

darkknight1999

Member

TrailRidden

New member

Incredible rebuild sir. It looks amazing. Its really something to cherish after all the hours you set aside for it. Again, great job. I wish you many years of wheeling in her! :beer: