With the weather being as nice as it has been, I decided to fire up Pappy and take him out to do some chores. Only problem was, it'd been a while since I last drove him and he made sure to let me know just how long that had been. While I didn't have too much trouble getting him started, he ran pretty rough - like he was missing a cylinder and idled like crap. After doing the usual checks for vacuum leaks, loose connections and timing, I decided to give his plugs a look and soon realized that a replacement of them was long overdue. Needless to say, today was a day for giving Pappy some luvin.

When I checked the timing, I did find it to be pretty off but even getting it set correctly to 5° BTDC didn't seem to really get him running smoothly. Being that I was going to be replacing the plugs and wires, I decided to remove the distributor cap so that I could check it and the rotor for cracks, carbon and evidence of arcing. And, while it wouldn't have hurt to replace them, they didn't look too bad but I did notice that the points didn't look quite right. As tiny as it may be, there should still be a visible gap and upon closer inspection, I found there was none. Needless to say, an adjustment here was needed.

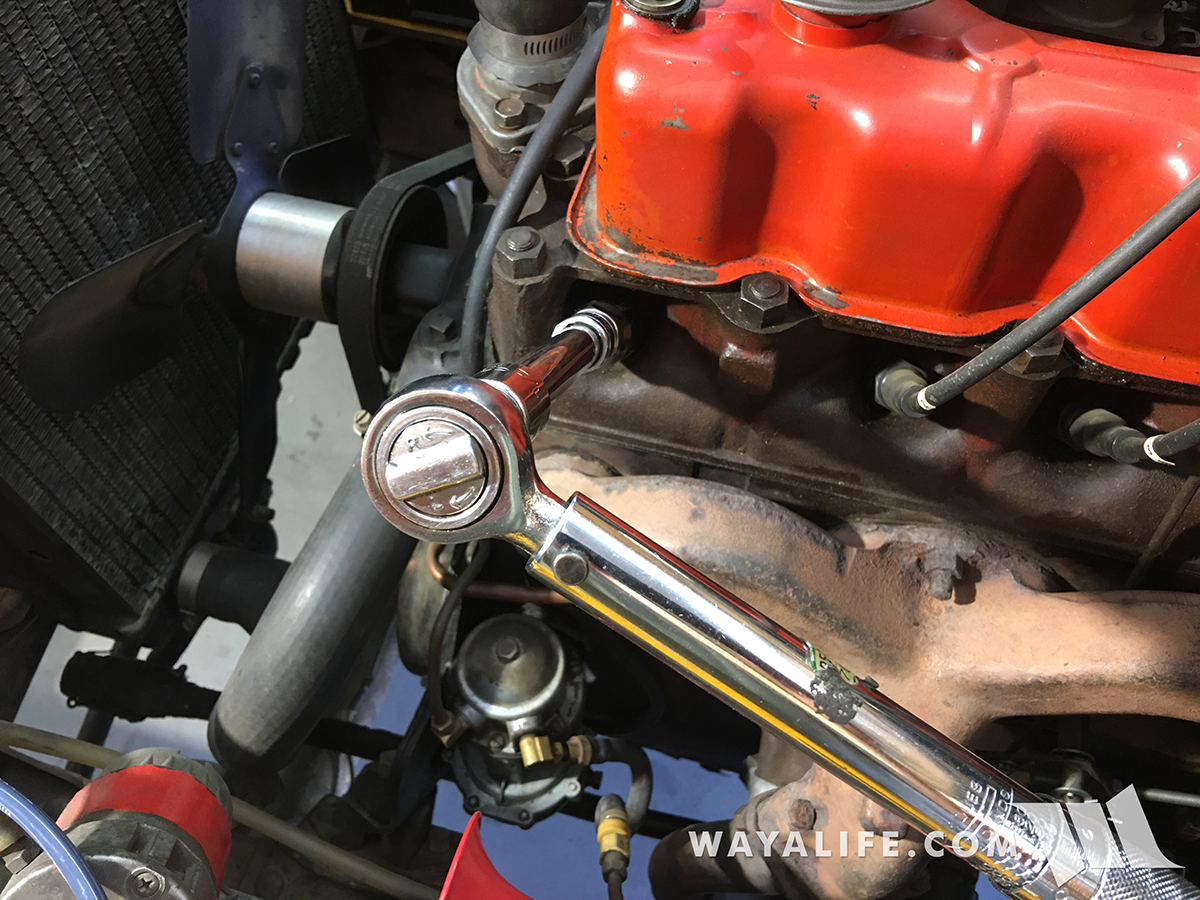

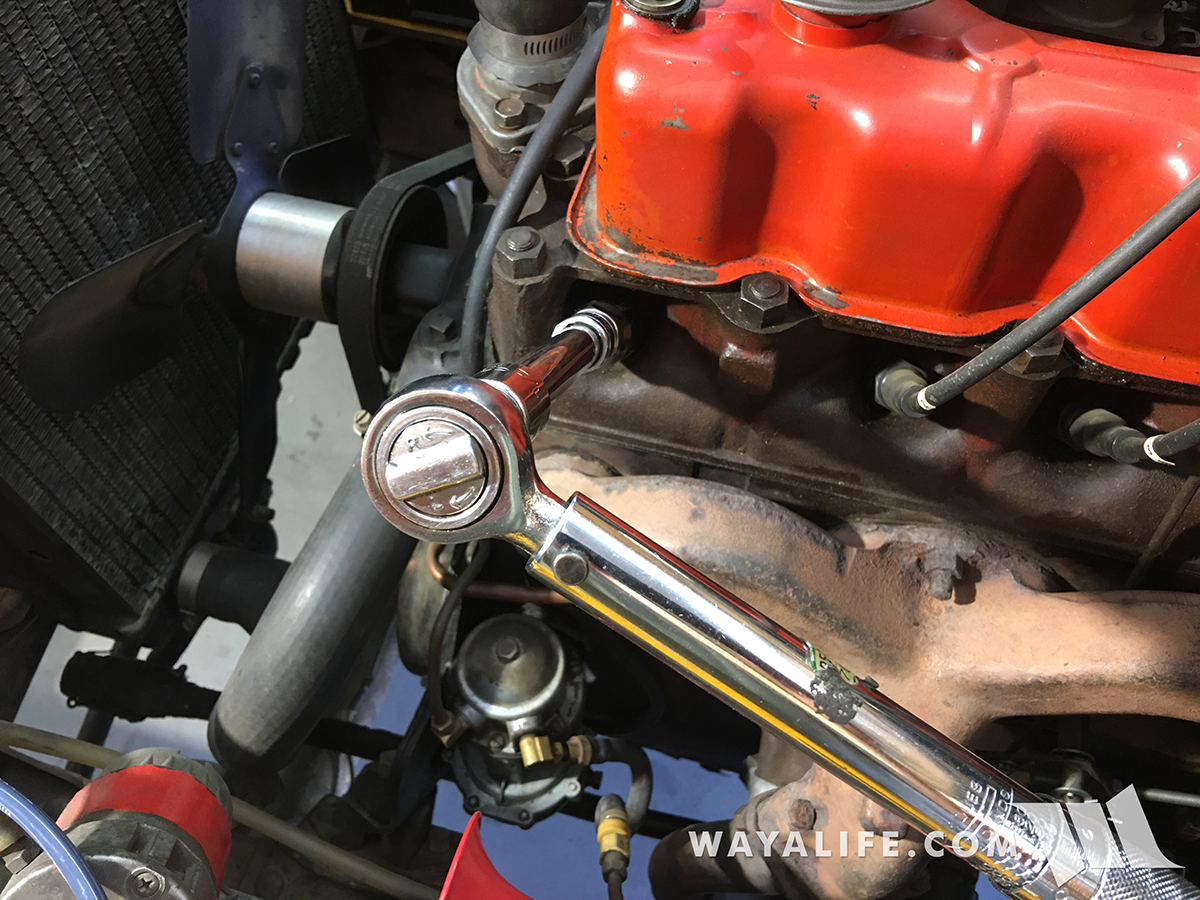

Verifying that the points now have a .020" gap.

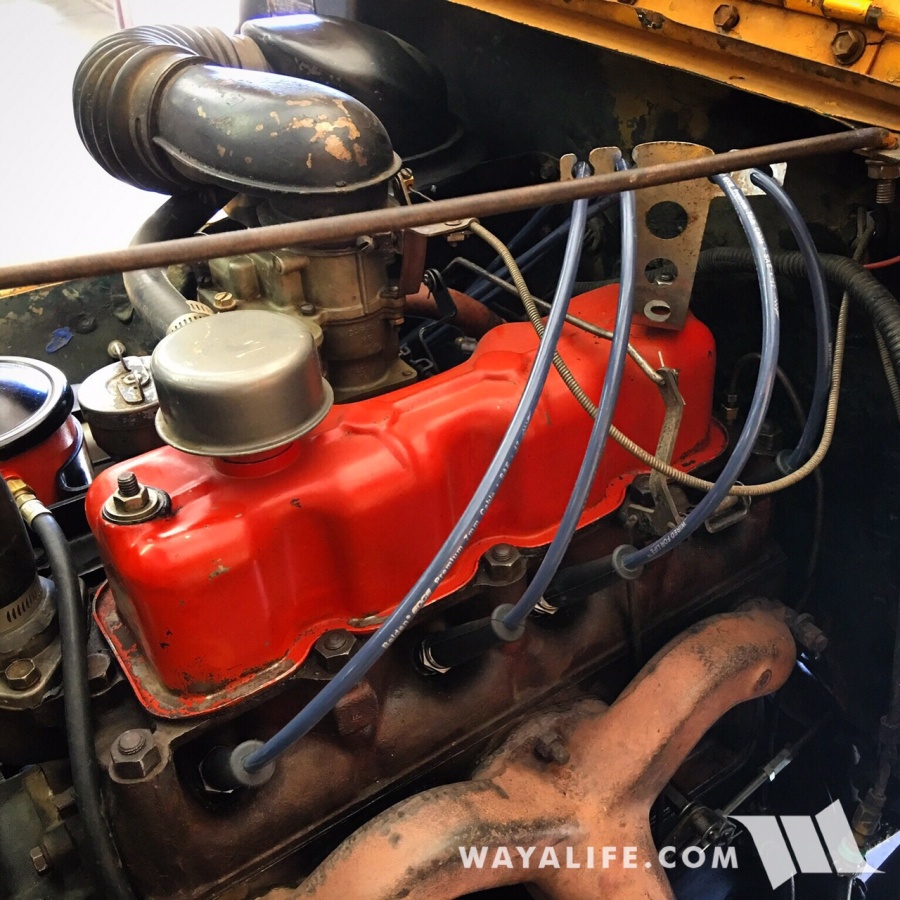

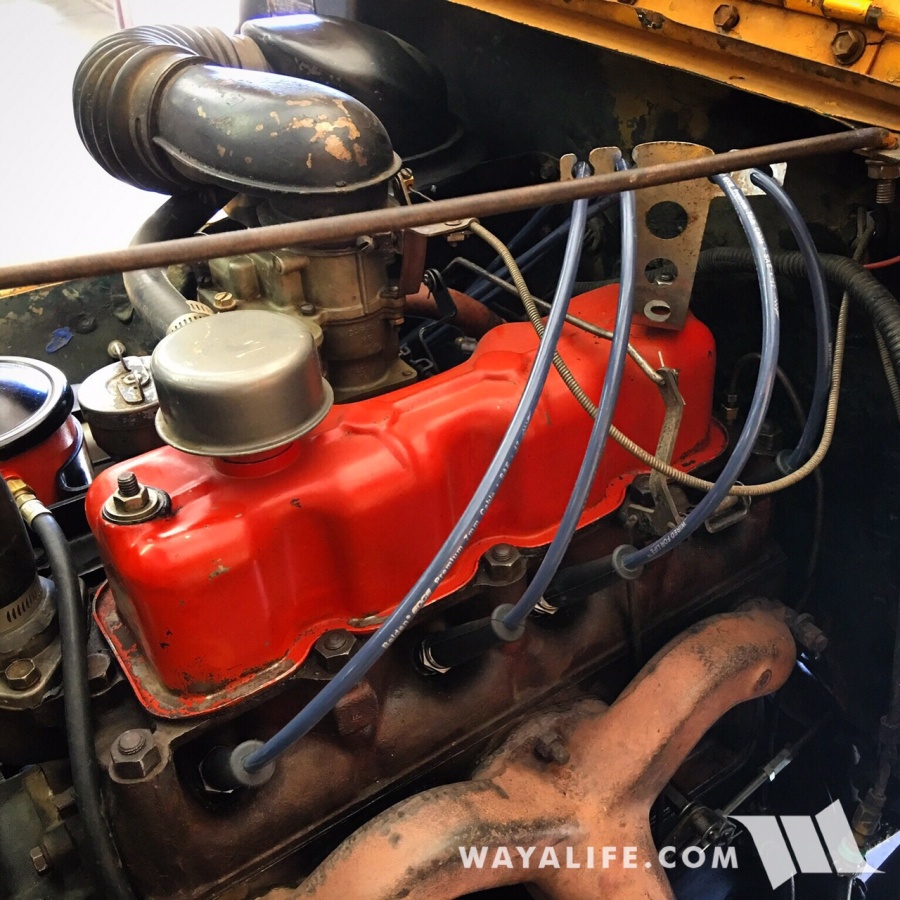

After a quick trip to my local Napa autoparts, I had a set of new Autolite plugs and wires for Pappy.

According to the factory service manual, the spark plugs on a Hurricane F4 engine need to be gapped at .030".

Applying a little antiseize to the threads of the spark plugs to help ensure they can be removed without too much fuss in the future.

Working one by one to help keep everything in order, I started off by removing the wire from plug #1.

Plug #1 can now be removed using a spark plug removal socket.

Here's a shot of what the plug looked like - just a bit of fouling. :icon_crazy:

Installing the new spark plug and tightening it to 20 ft. lbs or 240 in. lbs. of torque.

The new wires came with a small packet of dielectric grease and here you can see some being applied to the end of the spark plug.

Plugging in the new wire onto plug #1 and then repeat the process on the other 3.

Done! All new plugs and wires installed.

I'm happy to say that after installing the new plugs, wires and setting the points, Pappy's engine is running better than ever but still not as good as I'd prefer. Unfortunately, his idle still seems to be a bit off and I'll most likely have to tear into his carburetor to get to the bottom of that - perhaps, a project for tomorrow.

When I checked the timing, I did find it to be pretty off but even getting it set correctly to 5° BTDC didn't seem to really get him running smoothly. Being that I was going to be replacing the plugs and wires, I decided to remove the distributor cap so that I could check it and the rotor for cracks, carbon and evidence of arcing. And, while it wouldn't have hurt to replace them, they didn't look too bad but I did notice that the points didn't look quite right. As tiny as it may be, there should still be a visible gap and upon closer inspection, I found there was none. Needless to say, an adjustment here was needed.

Verifying that the points now have a .020" gap.

After a quick trip to my local Napa autoparts, I had a set of new Autolite plugs and wires for Pappy.

According to the factory service manual, the spark plugs on a Hurricane F4 engine need to be gapped at .030".

Applying a little antiseize to the threads of the spark plugs to help ensure they can be removed without too much fuss in the future.

Working one by one to help keep everything in order, I started off by removing the wire from plug #1.

Plug #1 can now be removed using a spark plug removal socket.

Here's a shot of what the plug looked like - just a bit of fouling. :icon_crazy:

Installing the new spark plug and tightening it to 20 ft. lbs or 240 in. lbs. of torque.

The new wires came with a small packet of dielectric grease and here you can see some being applied to the end of the spark plug.

Plugging in the new wire onto plug #1 and then repeat the process on the other 3.

Done! All new plugs and wires installed.

I'm happy to say that after installing the new plugs, wires and setting the points, Pappy's engine is running better than ever but still not as good as I'd prefer. Unfortunately, his idle still seems to be a bit off and I'll most likely have to tear into his carburetor to get to the bottom of that - perhaps, a project for tomorrow.