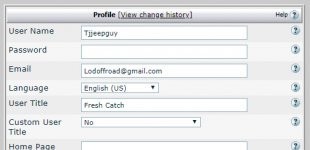

Well just to inform everyone. Anybody that does powder coating must touch up certain spots due to where the products are hung by hooks so they can spray them. The parts are hung on a powder coating line by a hook and all powder coating is done this way no matter who does it. We encourage you to look this up on youtube if you like so you have a good idea. So where the hook is touching the product no coating will be on this little spot. This spot must be touched up and of course we touch these little tiny spots up, everybody that does coating should as there is no way around this unless you can magically make the part hover (if so please let us know as we would love to hire you

. We outsource our coating as it is a very large undertaking and we let the guys that do coating do what they do best. We inspect everything before it ships and if something gets past us we would like to know it and will replace the product, mistakes can happen and we will always address them and take care of it. We do our best to constantly improve our process and work closley with out coater to improve everything from how they send the products back to us to the way they spray parts and hang them on the coating conveyer line. The nice thing part is anyone absolutley is set on their opinion and still wants our products, we offer them in bare steel and you can have it coated with any type of coating you would like

So feel free to contact us with any questions and we will be more than happy to help you out in any way we can.

LoD