JeepJeep75

New member

The next part of my build brings us to May of this year. Due to an ongoing hernia that I had, it was time to take some time off of work and get myself fixed up. During my down time I started collecting the next round of jeep parts. After much personal debate, and watching all the tube videos I could find of EVO sliders being installed and used on the rocks, I decided I would get a set. This was a big decision for me. There really isn't any going back once these babies are burned on. I ordered them up from Off Road Evolution and had them about 10 days later. I think they make these in batches because I did have to wait awhile. I didn't mind the wait because I could barely get off the couch during my recovery.

My sweet and very understanding wife had to drag them into the house for me. They lived on the floor in our living room for a few days until I could find help for her to get them into my toy room. Yes, I have a whole room filled with all of my junk, toys, and various precious items that someday I may or may not use.

They lived on the floor in our living room for a few days until I could find help for her to get them into my toy room. Yes, I have a whole room filled with all of my junk, toys, and various precious items that someday I may or may not use.

Also during my down-time I finally decided that the EVO Enforcer 3 inch lift was the lift for me. So a bunch of boxes with that exciting EVO tape started to pile up in my toy room as well. After a few weeks I was feeling good enough to start prepping the sliders for paint, and prepping the jeep for said sliders. I used an etching primer and fine textured black to paint them with.

Here they are all smoothed and primed. I used a flappy sanding disc on my grinder because I didn't want to completely smooth out the welds as they are flawless, but I wanted to get rid of the splatter that mig welding inevitably always leaves behind.

next was the black texture paint.

next was the black texture paint.

I decided to not put the EVO rocker skins on. I did however paint the pinch seams on the bottom of the jeep.

Before painting pinch seams:[emoji116]

After painting pinch seams:[emoji116]

doing this made those ugly seams with the holes almost completely disappear! Me likes!! [emoji16]

doing this made those ugly seams with the holes almost completely disappear! Me likes!! [emoji16]

So now the moment of truth. Time to burn these works of mechanical engineering art onto the jeep, forever! as I said at the beginning of this build, I'm not a welder. I know how to, and I do own my own machine, but I need a LOT more practice. Well, she ain't perty, but shill dance! [emoji6]

as I said at the beginning of this build, I'm not a welder. I know how to, and I do own my own machine, but I need a LOT more practice. Well, she ain't perty, but shill dance! [emoji6]

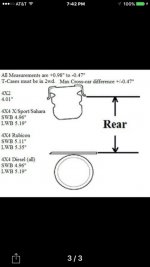

This job took me most of the day. Fitting, measuring, marking, removing paint, marking and measuring again...

Wiggling this big-ass mig gun around in those tight spaces, while laying on my side was not easy or very pleasurable but I managed to git er done. [emoji16]

My sweet and very understanding wife had to drag them into the house for me.

They lived on the floor in our living room for a few days until I could find help for her to get them into my toy room. Yes, I have a whole room filled with all of my junk, toys, and various precious items that someday I may or may not use.

They lived on the floor in our living room for a few days until I could find help for her to get them into my toy room. Yes, I have a whole room filled with all of my junk, toys, and various precious items that someday I may or may not use.

Also during my down-time I finally decided that the EVO Enforcer 3 inch lift was the lift for me. So a bunch of boxes with that exciting EVO tape started to pile up in my toy room as well. After a few weeks I was feeling good enough to start prepping the sliders for paint, and prepping the jeep for said sliders. I used an etching primer and fine textured black to paint them with.

Here they are all smoothed and primed. I used a flappy sanding disc on my grinder because I didn't want to completely smooth out the welds as they are flawless, but I wanted to get rid of the splatter that mig welding inevitably always leaves behind.

next was the black texture paint.

next was the black texture paint.

I decided to not put the EVO rocker skins on. I did however paint the pinch seams on the bottom of the jeep.

Before painting pinch seams:[emoji116]

After painting pinch seams:[emoji116]

doing this made those ugly seams with the holes almost completely disappear! Me likes!! [emoji16]

doing this made those ugly seams with the holes almost completely disappear! Me likes!! [emoji16]So now the moment of truth. Time to burn these works of mechanical engineering art onto the jeep, forever!

as I said at the beginning of this build, I'm not a welder. I know how to, and I do own my own machine, but I need a LOT more practice. Well, she ain't perty, but shill dance! [emoji6]

as I said at the beginning of this build, I'm not a welder. I know how to, and I do own my own machine, but I need a LOT more practice. Well, she ain't perty, but shill dance! [emoji6]

This job took me most of the day. Fitting, measuring, marking, removing paint, marking and measuring again...

Wiggling this big-ass mig gun around in those tight spaces, while laying on my side was not easy or very pleasurable but I managed to git er done. [emoji16]