I know it's all the rage to beef up a factory axle housing when planning to run bigger tires but, I can assure you that well before you'll ever come close to breaking a housing, you're almost certainly break a factory front axle shaft. Of course, being that the break will almost always happen at the u-joint, the assumption that many tend to make is that all u-joints suck and should be replaced with something more exotic and indestructable like a CV joint. But, before you drop some serious coin on a set of RCV's, I think it would be helpful to understand what is what, what exactly is going on and, why factory specific shafts tend to fail.

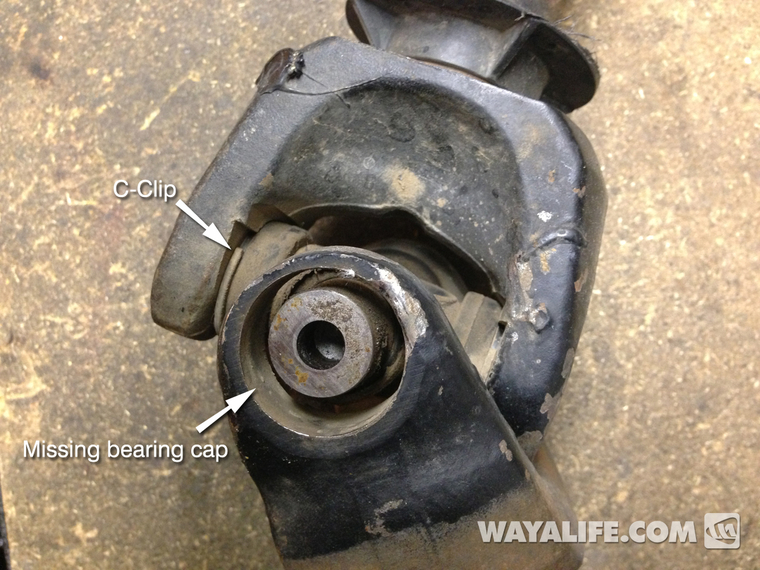

It is important to know that factory front axle shafts come with C-clips which are used to hold the u-joint bearing caps in place. Unfortuantely, time and a lot of wheeling will cause your u-joint bearing caps to rotate within the yokes. Over time, this rotation can cause the c-clips to pry off and once they're gone, it's just a matter of time before the bearing cap works itself free and falls out. Needless to say, without the bearing cap in place, the strength of your u-joint will be totally compromised and failure will occur. This is the most common cause of a factory front axle shaft break.

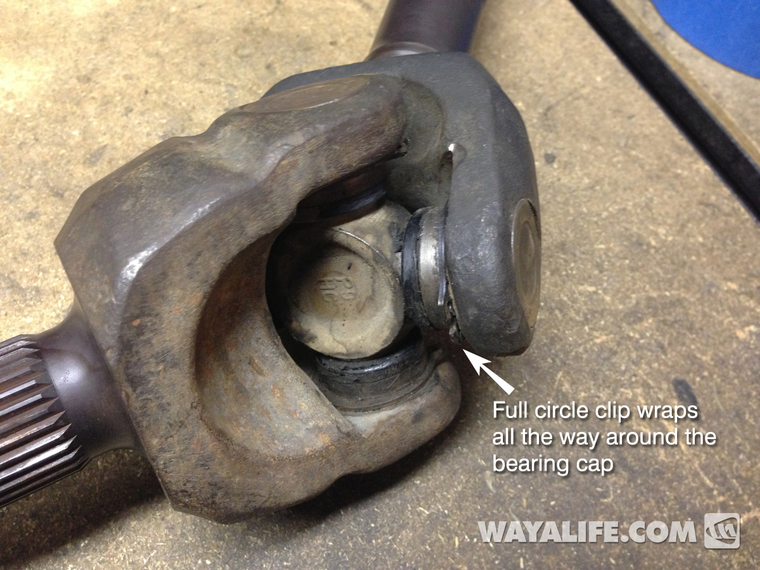

By comparison, most aftermarket chromoly front axle shafts are designed with yokes ears that will allow you to use full circle clips. As it's name implies, full circle clips wrap all the way around the bearing caps and by virtue of it, prevents them from ever coming off. In the photo below, will see a typical u-joint along with a standard C-clip on the left (what you find standard on a factory axle shaft) and a full circle clip on the right (what you typically find on an aftermarket chromoly shaft).

In this photo, you will see how a standard C-clip is installed and what can happen if it gets pried off. Once it's gone, there's little to hold the bearing cap in place.

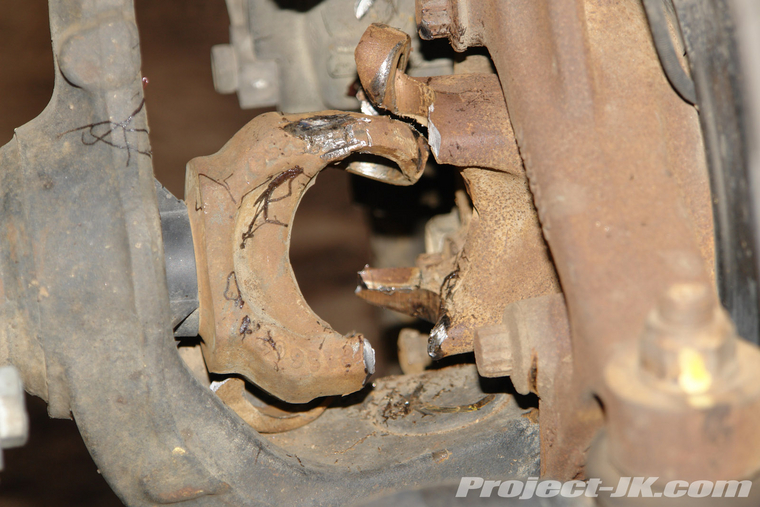

This is a photo of what a typical factory front axle break looks like. As you can see, it occured at the u-joint and most likely because of a bearing cap had been lost.

And, here is a photo of what a chromoly shaft with full circle clips installed looks like. As you will see, the full circle clips go all the way around the bearing caps and cannot be pried off. This feature alone will help prevent an axle shaft break and for a lot less than a set of RCV shafts with CV joint.

Now, don't get me wrong, RCV's are really nice shafts and ones that I've run before. I just don't know if they're really something you need. At least, it has been my experience that standard aftermarket chromoly shafts will do the job just as well and at a considerably lower price. Certainly, with the money you save, there are a lot of other pricy mods you can buy or be well on the way to getting. Of course, this is all just my opinion based on my experiences. The purposes of this article is not to convince you to buy one thing or another but rather, explain the differences between a c-clip and a full circle clip and to show why factory specific front axle shafts tend to fail. I hope this has been helpful. :yup:

It is important to know that factory front axle shafts come with C-clips which are used to hold the u-joint bearing caps in place. Unfortuantely, time and a lot of wheeling will cause your u-joint bearing caps to rotate within the yokes. Over time, this rotation can cause the c-clips to pry off and once they're gone, it's just a matter of time before the bearing cap works itself free and falls out. Needless to say, without the bearing cap in place, the strength of your u-joint will be totally compromised and failure will occur. This is the most common cause of a factory front axle shaft break.

By comparison, most aftermarket chromoly front axle shafts are designed with yokes ears that will allow you to use full circle clips. As it's name implies, full circle clips wrap all the way around the bearing caps and by virtue of it, prevents them from ever coming off. In the photo below, will see a typical u-joint along with a standard C-clip on the left (what you find standard on a factory axle shaft) and a full circle clip on the right (what you typically find on an aftermarket chromoly shaft).

In this photo, you will see how a standard C-clip is installed and what can happen if it gets pried off. Once it's gone, there's little to hold the bearing cap in place.

This is a photo of what a typical factory front axle break looks like. As you can see, it occured at the u-joint and most likely because of a bearing cap had been lost.

And, here is a photo of what a chromoly shaft with full circle clips installed looks like. As you will see, the full circle clips go all the way around the bearing caps and cannot be pried off. This feature alone will help prevent an axle shaft break and for a lot less than a set of RCV shafts with CV joint.

Now, don't get me wrong, RCV's are really nice shafts and ones that I've run before. I just don't know if they're really something you need. At least, it has been my experience that standard aftermarket chromoly shafts will do the job just as well and at a considerably lower price. Certainly, with the money you save, there are a lot of other pricy mods you can buy or be well on the way to getting. Of course, this is all just my opinion based on my experiences. The purposes of this article is not to convince you to buy one thing or another but rather, explain the differences between a c-clip and a full circle clip and to show why factory specific front axle shafts tend to fail. I hope this has been helpful. :yup: