zeddjb

New member

Hey everyone!! It's been a while since I posted anything on here. I'm looking for some help with my 2012 JK Rubi. I recently replaced the front drive shaft from stock to a JE Reel 1310 Heavy Duty CV from NorthRidge 4x4. The reason for the replacement was to resolve an issue with some "clackity clack" type sound which I thought was the front joint failing. (I have had that in the past so I figured that was the issue)

Upon receiving the new shaft, I removed the old (stock) one and inspected it, to find the boot still intact and just fine...Okay then...Replaced anyways because why not. The "clackity clack" sound still remains and seems like its getting worse (read: louder). Also, at speeds of 65+ MPH, there is a really terrible vibration under my feet. Having it in 4-Hi/Lo doesn't seem to make a difference with the sound. Also, the sound seems to start right about 5 to 10 MPH; whether I am accelerating or decelerating. When accelerating the sounds is drown out by the engine and the tires.

I called NorthRidge 4x4, thinking the shaft must be out of balance from manufacturer; the manufacture sent me a new one but all the same issues persist. I am currently running with no front drive shaft and the Jeep drives as expected. No sounds, no vibrations (had it past 80+ MPH).

Things I have tried and done:

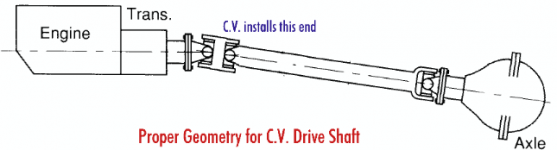

I'm really lost as to what the issue is. One shop I took it to said that I need to drop my transfer case lower because the drive shaft is at a weird angle. I thought that was the point of the double cardan drive shaft was to help assist with geometry issues.(maybe my assumption isn't accurate?)

Some Relative Specs:

2012 Jeep JK Rubicon

37 inch AT tires

4 inch suspension lift kit; no body lift

Thanks for reading all of this babble. I hope something makes sense to someone. Let me know if anyone has any additional questions I can answer. Thanks everyone!!

Upon receiving the new shaft, I removed the old (stock) one and inspected it, to find the boot still intact and just fine...Okay then...Replaced anyways because why not. The "clackity clack" sound still remains and seems like its getting worse (read: louder). Also, at speeds of 65+ MPH, there is a really terrible vibration under my feet. Having it in 4-Hi/Lo doesn't seem to make a difference with the sound. Also, the sound seems to start right about 5 to 10 MPH; whether I am accelerating or decelerating. When accelerating the sounds is drown out by the engine and the tires.

I called NorthRidge 4x4, thinking the shaft must be out of balance from manufacturer; the manufacture sent me a new one but all the same issues persist. I am currently running with no front drive shaft and the Jeep drives as expected. No sounds, no vibrations (had it past 80+ MPH).

Things I have tried and done:

- Replaced the AT+4 transfer case oil. No shavings or any foreign material found on magnets. Oil was a bit discolored but not bad by any standards.

- Replaced the front (and rear) diff fluid. Front done twice and used new fluid each time. Small amount of shavings on magnets.

- Had front diff cover off to look at gears and it looks normal.

I'm really lost as to what the issue is. One shop I took it to said that I need to drop my transfer case lower because the drive shaft is at a weird angle. I thought that was the point of the double cardan drive shaft was to help assist with geometry issues.(maybe my assumption isn't accurate?)

Some Relative Specs:

2012 Jeep JK Rubicon

37 inch AT tires

4 inch suspension lift kit; no body lift

Thanks for reading all of this babble. I hope something makes sense to someone. Let me know if anyone has any additional questions I can answer. Thanks everyone!!