You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

68' M715 AKA "Smokey", 8.1 engine on links, coils and 40's

- Thread starter Rock40

- Start date

Rock40

Active Member

Haha! Absolutely trueYou can never have too many USBs.

Rock40

Active Member

Yeah, my rough guess is probably right around 6k. I believe they are about 5k originally and I’ve added a lot of steel at this pointDo you have a ballpark on the finished weight when you’re done?

Rock40

Active Member

Sort of a lazy Sunday so it’s NP205 time….

Fortunately Mark and I label all this stuff when it comes apart. Years later I’d have no clue what it came out of. This 205 is from an ‘89 Chevrolet K30 crewcab truck from Fairbanks, AK. It was a former Alyeska Pipeline truck with a 6.2 liter diesel. This case has the more desirable large input bearing

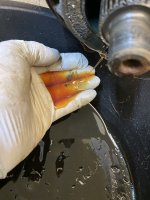

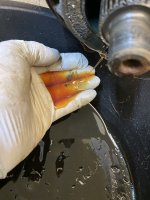

Oil looked good…

It’s apart. Internals look great but for some odd reason the inside of the 205 case is rusty. Easy fix, I’ll take that over junk internals

Fortunately Mark and I label all this stuff when it comes apart. Years later I’d have no clue what it came out of. This 205 is from an ‘89 Chevrolet K30 crewcab truck from Fairbanks, AK. It was a former Alyeska Pipeline truck with a 6.2 liter diesel. This case has the more desirable large input bearing

Oil looked good…

It’s apart. Internals look great but for some odd reason the inside of the 205 case is rusty. Easy fix, I’ll take that over junk internals

Rock40

Active Member

Blasted and nearly ready for paint and reassembly. Flat surfaces got smoothed with a DA

No more rust on the inside now

So here’s some input shaft comparison. The middle shaft is a new “Fat Shaft” from Off-Road Design. Left shaft is from this case and the right shaft is from a different 205 altogether. The left shaft is internally splined. Note that the ORD shaft is far bigger and more robust

Another ORD shaft on top, OEM 205 on the bottom. The goal is brute strength, all the internal shafts are being replaced/upgraded

No more rust on the inside now

So here’s some input shaft comparison. The middle shaft is a new “Fat Shaft” from Off-Road Design. Left shaft is from this case and the right shaft is from a different 205 altogether. The left shaft is internally splined. Note that the ORD shaft is far bigger and more robust

Another ORD shaft on top, OEM 205 on the bottom. The goal is brute strength, all the internal shafts are being replaced/upgraded

Brute

Hooked

My Brute pickup weighed in at 6300 unloaded and little fuel (before rtt, awning and more bed tube)…don’t be surprised if you’re not near 7000Yeah, my rough guess is probably right around 6k. I believe they are about 5k originally and I’ve added a lot of steel at this point

Rock40

Active Member

My Brute pickup weighed in at 6300 unloaded and little fuel (before rtt, awning and more bed tube)…don’t be surprised if you’re not near 7000

Oooof, that’s a heavy sucker. The drivetrain can certainly take it but I’m hoping it’s not THAT heavy for off-road stuff

Rock40

Active Member

Shifting gears a bit…

I’ve been putting off the sheet metal and rocker replacement because I dislike body work so much. Time to just get it over with

It’s pretty hard to find panels for this vintage FSJ. We had ordered rockers from BJ’s off-road but the fitment was TERRIBLE. None of the contours matched the original lines and they are made in Taiwan. After going back and forth with them, they admitted they were aware of some fitment problems and were “working on it”. Over 6 months later with no progress, my buddy just bent some up locally. I still needed to use the cab corner and pillar from BJ’s tho, fortunately, those pieces were ballpark close. No where near great, but close enough after cutting some of the bends and contours out

I’ve been putting off the sheet metal and rocker replacement because I dislike body work so much. Time to just get it over with

It’s pretty hard to find panels for this vintage FSJ. We had ordered rockers from BJ’s off-road but the fitment was TERRIBLE. None of the contours matched the original lines and they are made in Taiwan. After going back and forth with them, they admitted they were aware of some fitment problems and were “working on it”. Over 6 months later with no progress, my buddy just bent some up locally. I still needed to use the cab corner and pillar from BJ’s tho, fortunately, those pieces were ballpark close. No where near great, but close enough after cutting some of the bends and contours out

wjtstudios

Hooked

So much work, amazing

Mile High JK

Member

Really impressed with the amount of work and attention to detail going into this build.

Rock40

Active Member

This build is truly awesome. Can’t wait to see the finished product.

Looks great! Cool to see that the internals of the TC held up that well!

So much work, amazing

Really impressed with the amount of work and attention to detail going into this build.

Thanks for the encouragement everyone!! Got a bit closer today and managed to finesse the driver cab corner into place!

Reinforced the interior of the “B” pillar

Made supports for the upper part of the cab corner

One example of many regarding how poorly these panels fit. The original 90 degree break in the sheet metal left the panel WAY too long to correctly line up with the flange inside the cab. So, you cut the panel down and weld a length of steel in lengthwise so things actually line up

Rock40

Active Member

Moving on to something less tedious than sheet metal work.

1.5” spacers arrived from Wheeladapter.com These are machined from Timken steel and use a 10.9 wheel stud. MUCH stronger than OEM.

These were needed to give us a bit more clearance at extreme articulation as the tire is quite close to the coil over

The fit was excellent, these are a very quality spacer

1.5” spacers arrived from Wheeladapter.com These are machined from Timken steel and use a 10.9 wheel stud. MUCH stronger than OEM.

These were needed to give us a bit more clearance at extreme articulation as the tire is quite close to the coil over

The fit was excellent, these are a very quality spacer

Rock40

Active Member

Monkeying with the exhaust again. And HAPPY NEW YEAR!

Added quick disconnect flanges to all 3 ends of the cross over pipe

Stainless flex joint and Borla muffler…

Snaking it through the cross member, this is a full 3” exhaust from the headers back

Stainless hangers with insulators, again used weld in nutserts to mount them

2nd Borla muffler and a bit of tube, this gets the exhaust out and over the rear axle with room to spare at full bump. Little more exhaust to go tho

Added quick disconnect flanges to all 3 ends of the cross over pipe

Stainless flex joint and Borla muffler…

Snaking it through the cross member, this is a full 3” exhaust from the headers back

Stainless hangers with insulators, again used weld in nutserts to mount them

2nd Borla muffler and a bit of tube, this gets the exhaust out and over the rear axle with room to spare at full bump. Little more exhaust to go tho

Last edited: