gfrench

Member

I now have the body off my CJ5 rebuild project and have a question on the suspension and transfer case position.

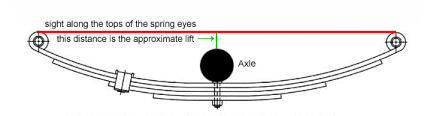

Not being real familiar with the set up I have here.... I see there are shackles on the front and rear Leaf springs- measures 3 " from center of bottom bolt to center of top bolt. What would be considered stock height? 3"?

Also the skid plate/transfer case has been dropped 1 1/2" does this make sense and appropriate? want to put in all new bushings in the leafs and a better shims for the skid plate.

Just want to know if this all sounds right and the way it should be. I was wondering why the engine had a definite tilt upward and now see with the transfer case lowered 1 1/2" would explain it.

So with this set up guessing I should leave the skid plate/transer case lowered as is?

Thanks for any help and or direction here- appreciate it,

No bushings left in those leaf springs so what a difference that will make once all back together right.

Not being real familiar with the set up I have here.... I see there are shackles on the front and rear Leaf springs- measures 3 " from center of bottom bolt to center of top bolt. What would be considered stock height? 3"?

Also the skid plate/transfer case has been dropped 1 1/2" does this make sense and appropriate? want to put in all new bushings in the leafs and a better shims for the skid plate.

Just want to know if this all sounds right and the way it should be. I was wondering why the engine had a definite tilt upward and now see with the transfer case lowered 1 1/2" would explain it.

So with this set up guessing I should leave the skid plate/transer case lowered as is?

Thanks for any help and or direction here- appreciate it,

No bushings left in those leaf springs so what a difference that will make once all back together right.

Last edited: