One of the cheapest and easiest things you can do to improve the quality of your Jeep JL Wrangler or JT Gladiator's ride and overall performance off-road, is to air down your tires before hitting the trail. Reducing the PSI or lowering pressure in your tires will do wonders to soften things up on easy dirt roads and give you a greater degree of traction, out on the rocks. Obviously, letting air out of your tires is the easy part but how to get it back in at the end of the day... now that's the real question. Of course, the easiest solution to this problem would be to carry a portable air compressor or even something like a CO2 tank but if you're anything like me and carry a ton of gear, real estate can be in short supply. Needless to say, that's why I decided to make, the WAYALIFE ACM.

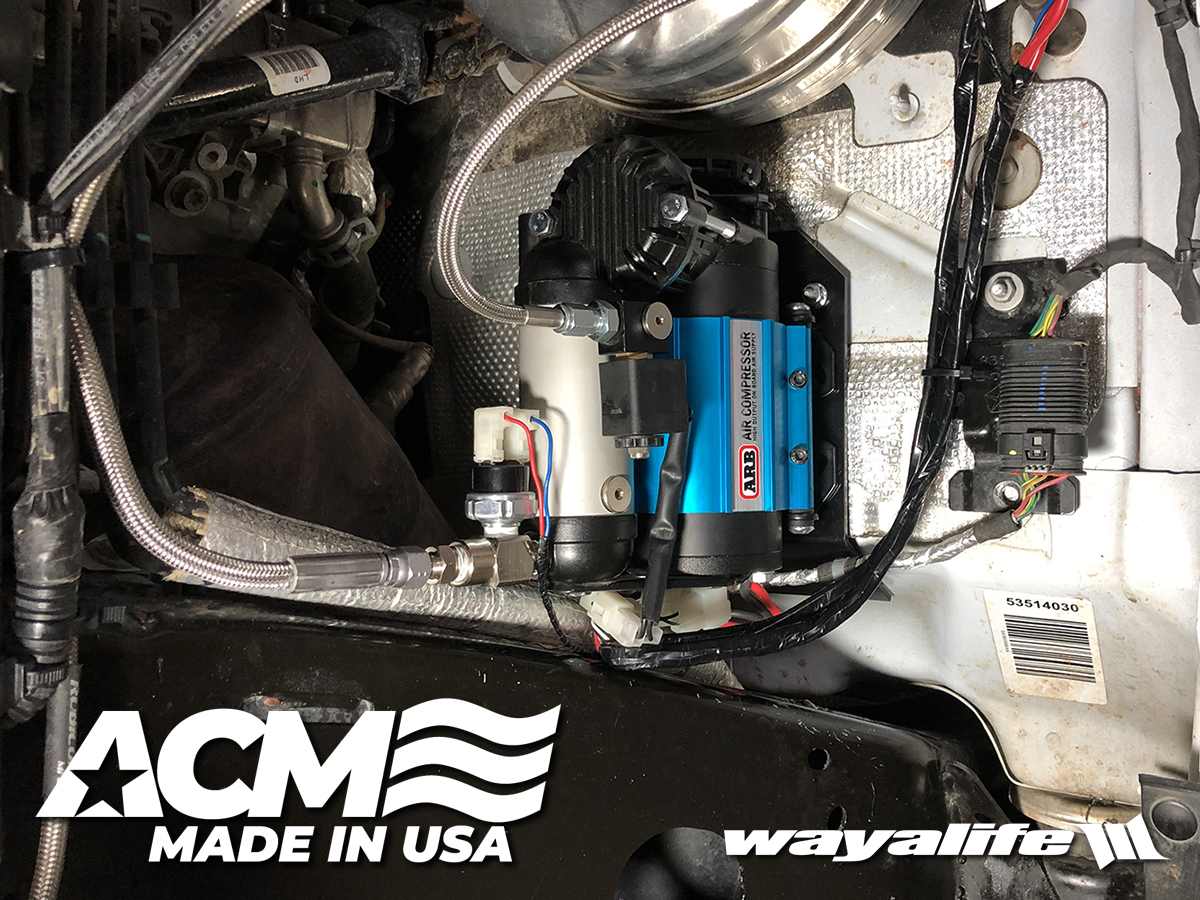

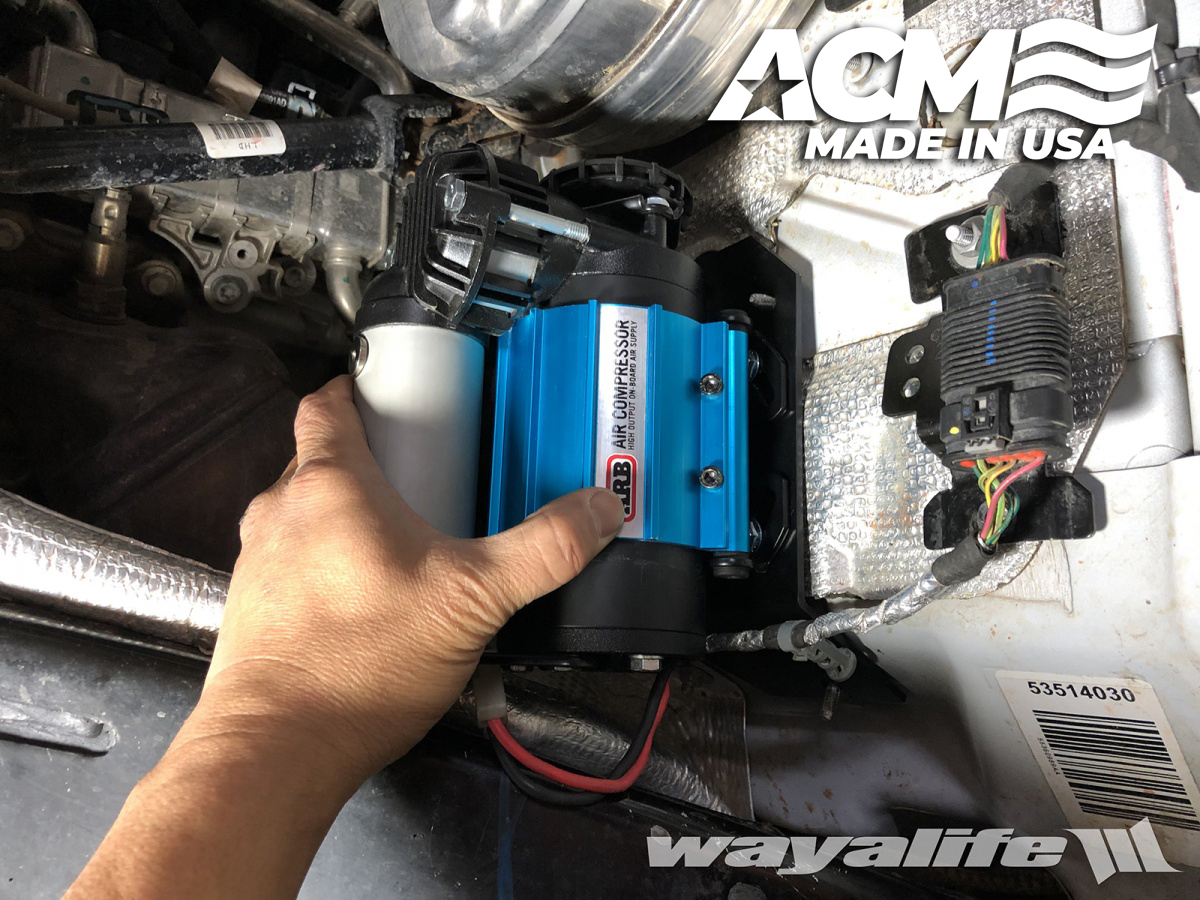

The WAYALIFE ACM is designed to work with an ARB CKMA12 Air Compressor (a 12V high output on board air compressor that I've used for years, on multiple Jeeps and have always found to work well) and allow you to mount it outside the cabin of your JL Wrangler or JT Gladiator and safely under the hood. Installed up against the firewall and under the brake booster, you can access the air chuck from behind the fender liner near the shock tower or you can run a hose extension to a chuck located remotely on your Jeep. Also, if you're wanting to run ARB air lockers on your factory axles or on something like a Dynatrac ProRock 44, the ACM will help make plumbing air lines to the compressor super easy as well. Removal of the driver side fender to install everything will be necessary but otherwise, absolutely no drilling or cutting is required.

CLICK on the Links Below to BUY

WAYALIFE ACM JL Wrangler / JT Gladiator Air Compressor Mount

ARB CKMA12 High Output On-Board 12V Air Compressor : https://amzn.to/2OtgwaF

ARB Air Hose Accessory Kit : https://amzn.to/2OrLRut

ARB JIC-04 Extension Hose 1M : https://amzn.to/2OBT1fP

ARB 171314 Remote Hose Coupling Kit : https://amzn.to/2OwcX3t

Package Contents

(1) WAYALIFE ACM

(2) 4mm Spacers

(1) 6mm Spacer

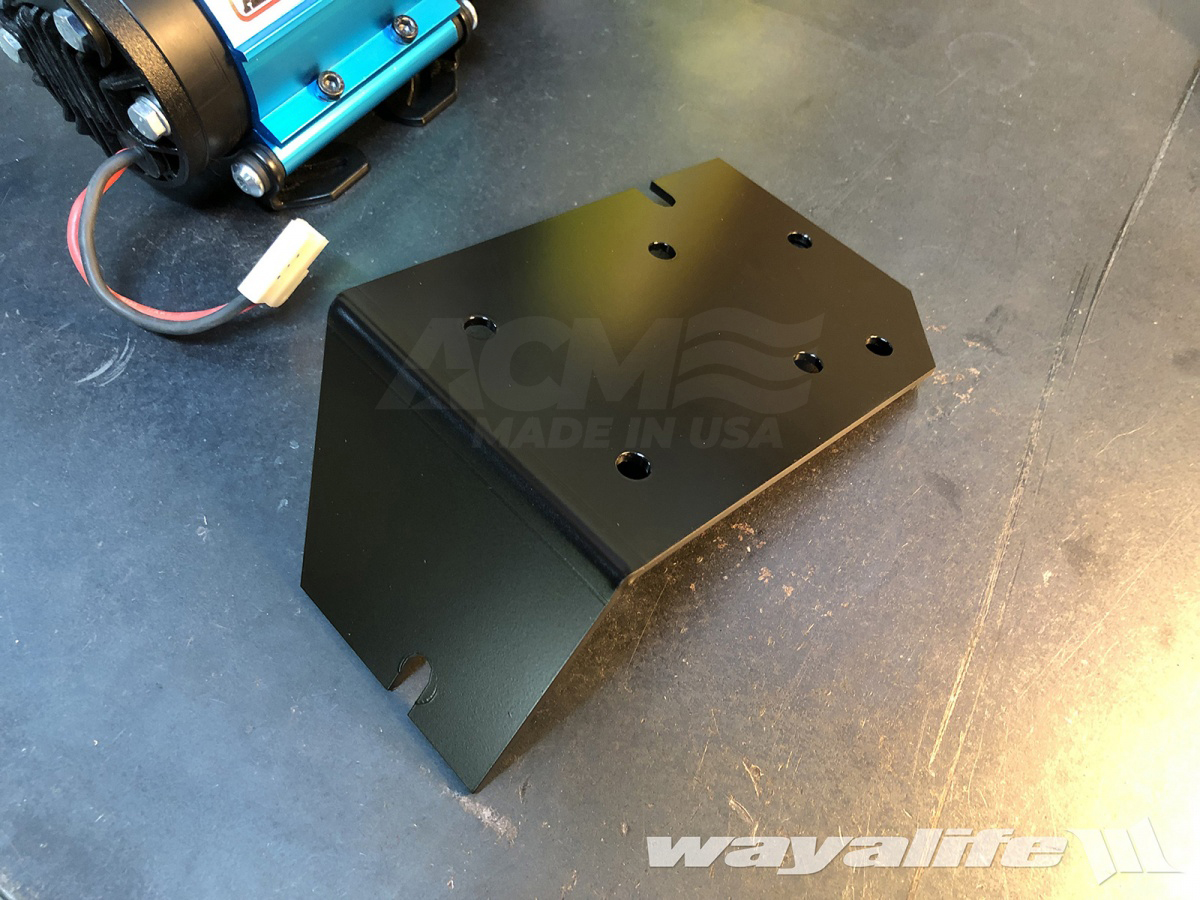

(4) M6x1.0 Serrated Flange Nuts

(1) M6 Washer

(4) 1/4"-20x1/2" Bolts

(4) 1/4"-20 Serrated Flange Nuts

What You Will Need

• 10mm Wrench & Socket

• 19mm Wrench

• 3, 4mm Allen Wrench

• 7/16" Wrench & Socket*

• Crescent Wrench

• Trim Tab Pry Tool

• Teflon Tape

• Spare Fender Clips

*NEW : As of 01/18/2020, the ACM now comes with all metric hardware! All you need is a 10mm wrench to install the mount.

Instructions

1. Park your JL Wrangler or JT Gladiator on a level surface and prop open the hood. While it isn't necessary to do, placing your front axle on jack stands and removing the driver side tire will give you a lot more room to work with.

2. Using a trim pry tool, remove the plastic push tab securing the fender liner to the body just behind the grill.

3. Using a 10mm socket, remove the 4 bolts securing the fender liner to the body as shown.

4. Firmly grab your fender from about the middle to the back and pull it forcefully and abruptly out about an inch. You just want to pull hard enough and far enough to free up the trim tabs. Repeat this on the front half of the fender.

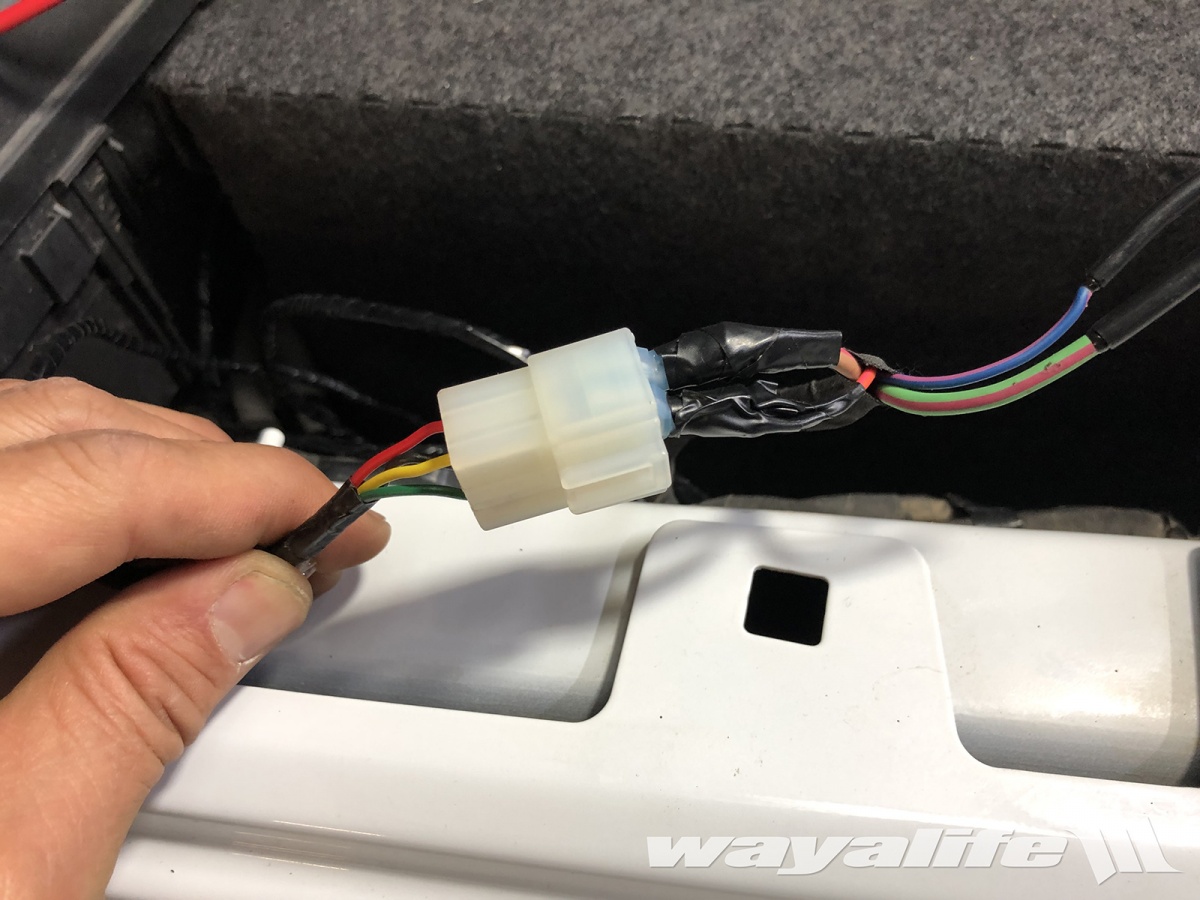

5. Pull the loose fender away from the body just enough to reveal the wiring harness. Pull the red tab out to unlock it and then disconnect it by squeezing the plug firmly as shown.

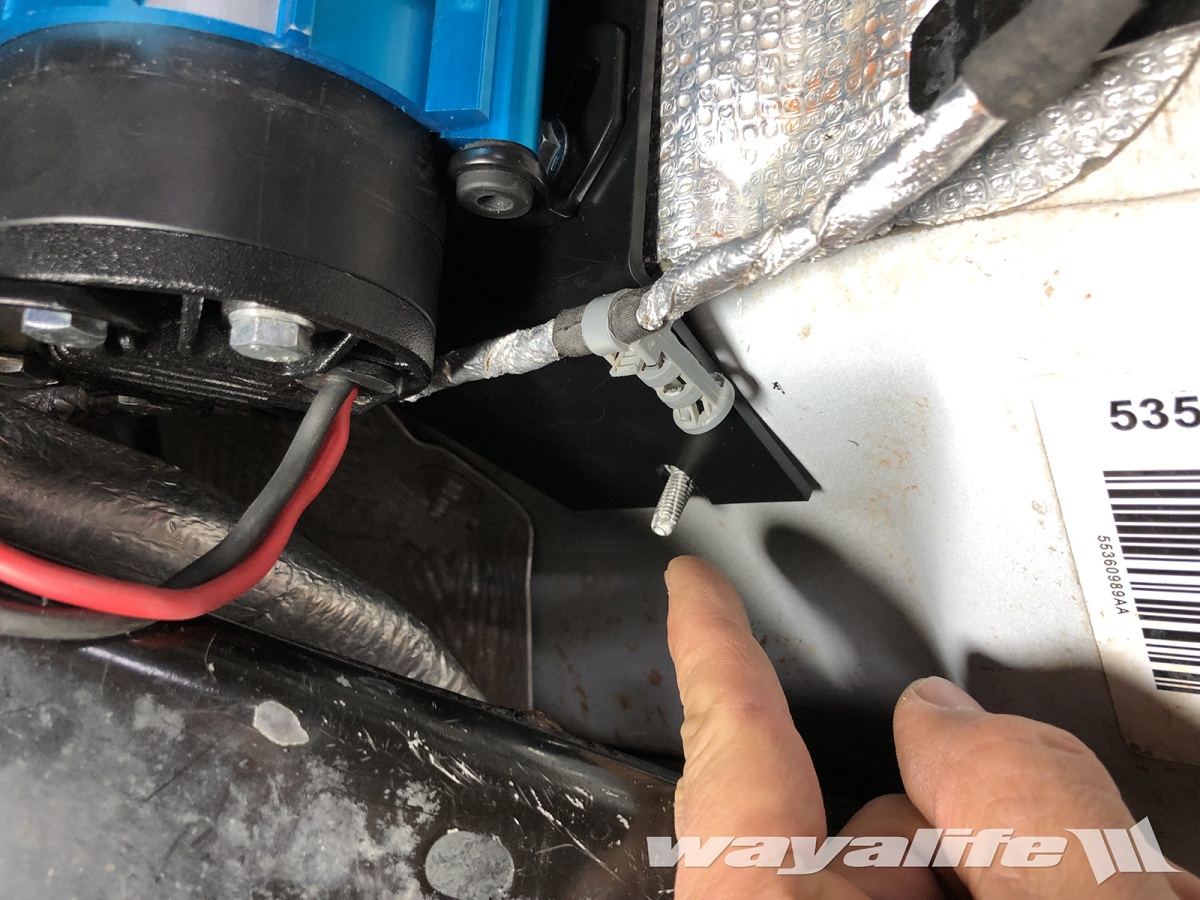

6. Along the firewall, you will see wiring that's secured to a stud with a gray plastic clip. Pull on the clip to free it from the stud.

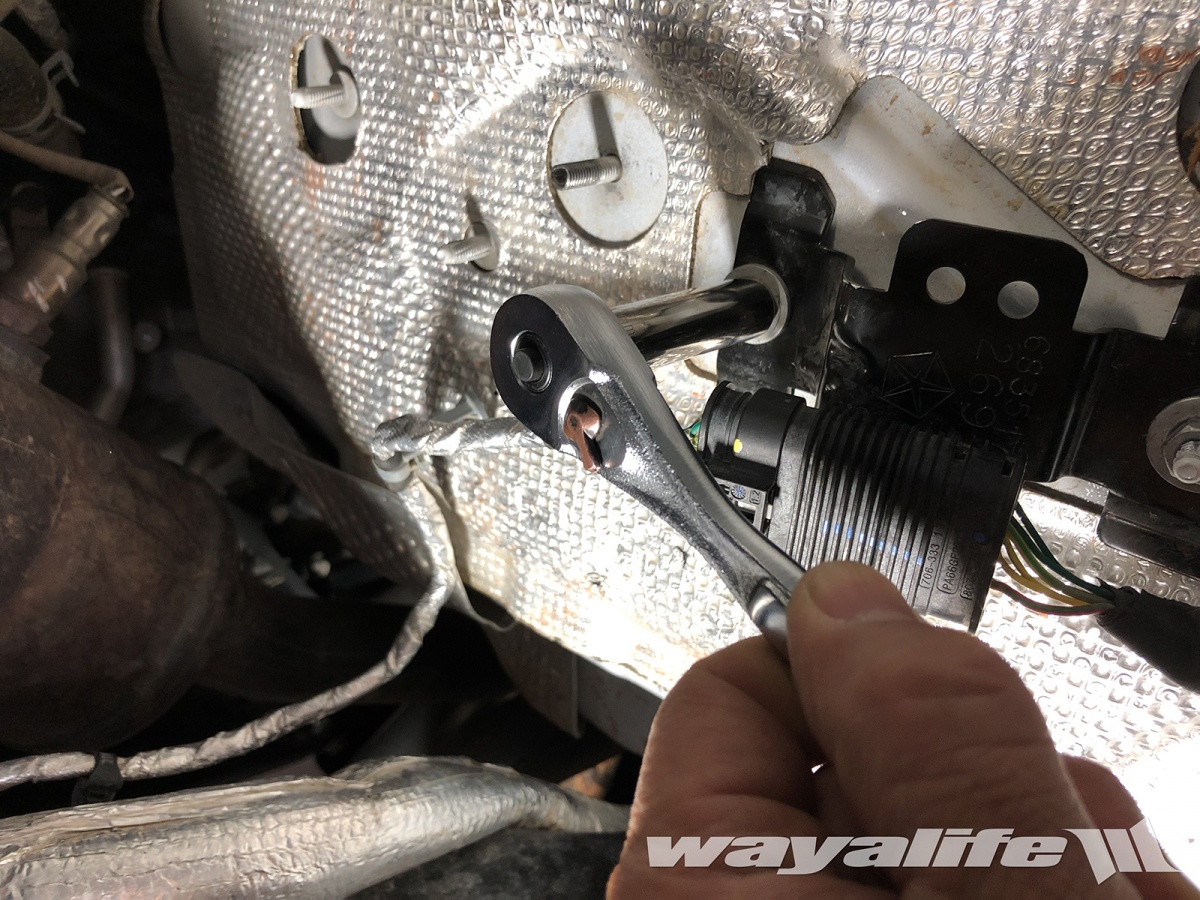

7. Using a 10mm socket, remove the nut closest to the engine that's securing the metal bracket with a plug on it to the firewall.

8. Using a 10mm socket, loosen but do not remove the other nut securing the metal bracket to the firewall.

9. Pull the free end of the metal bracket off the mounting stud, rotate it downward and then tighten up the remaining nut using a 10mm socket.

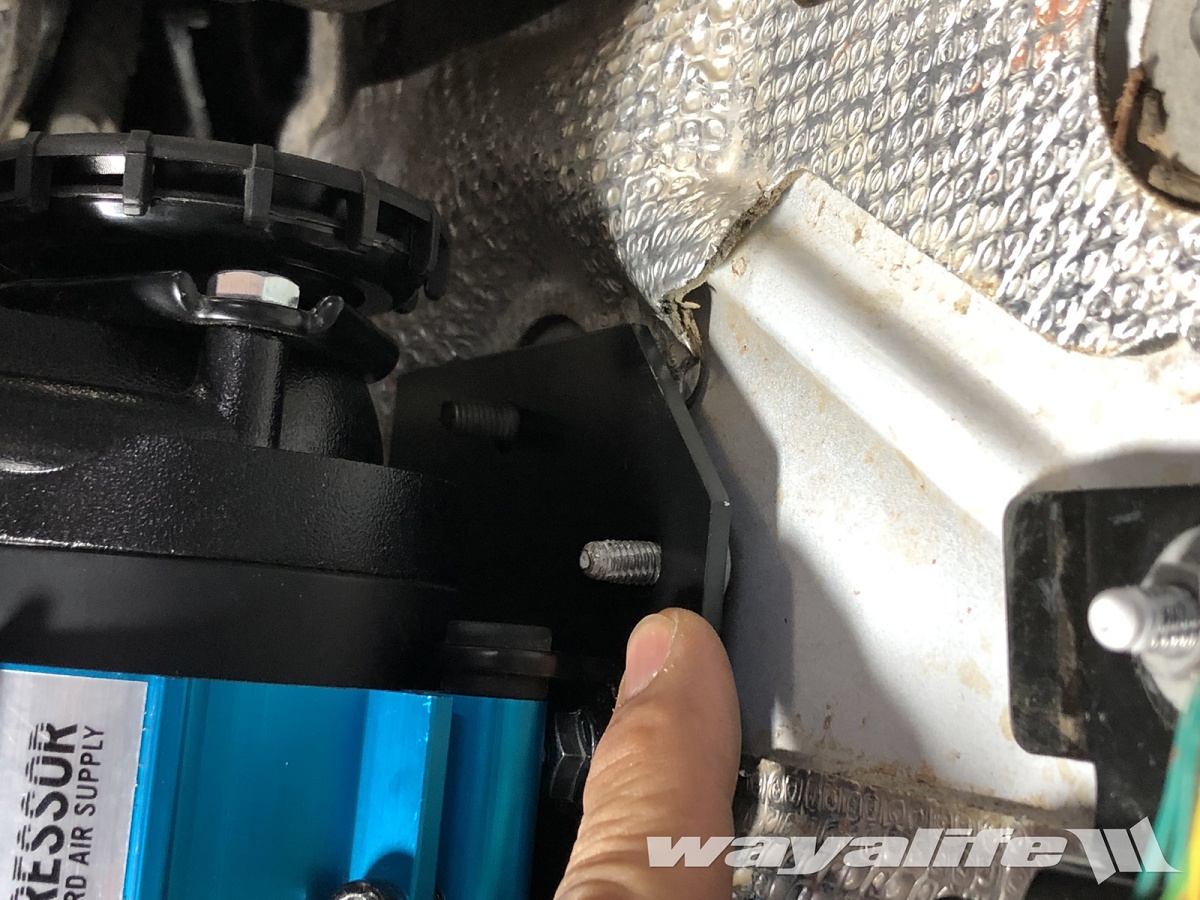

10. Place the 6mm spacer onto the middle of the 3 studs located on the firewall and to the left of the metal bracket.

11. Place the 2 remaining 4mm spacers on the other 2 firewall studs.

12. Place your WAYALIFE ACM on a work bench with the front side facing up.

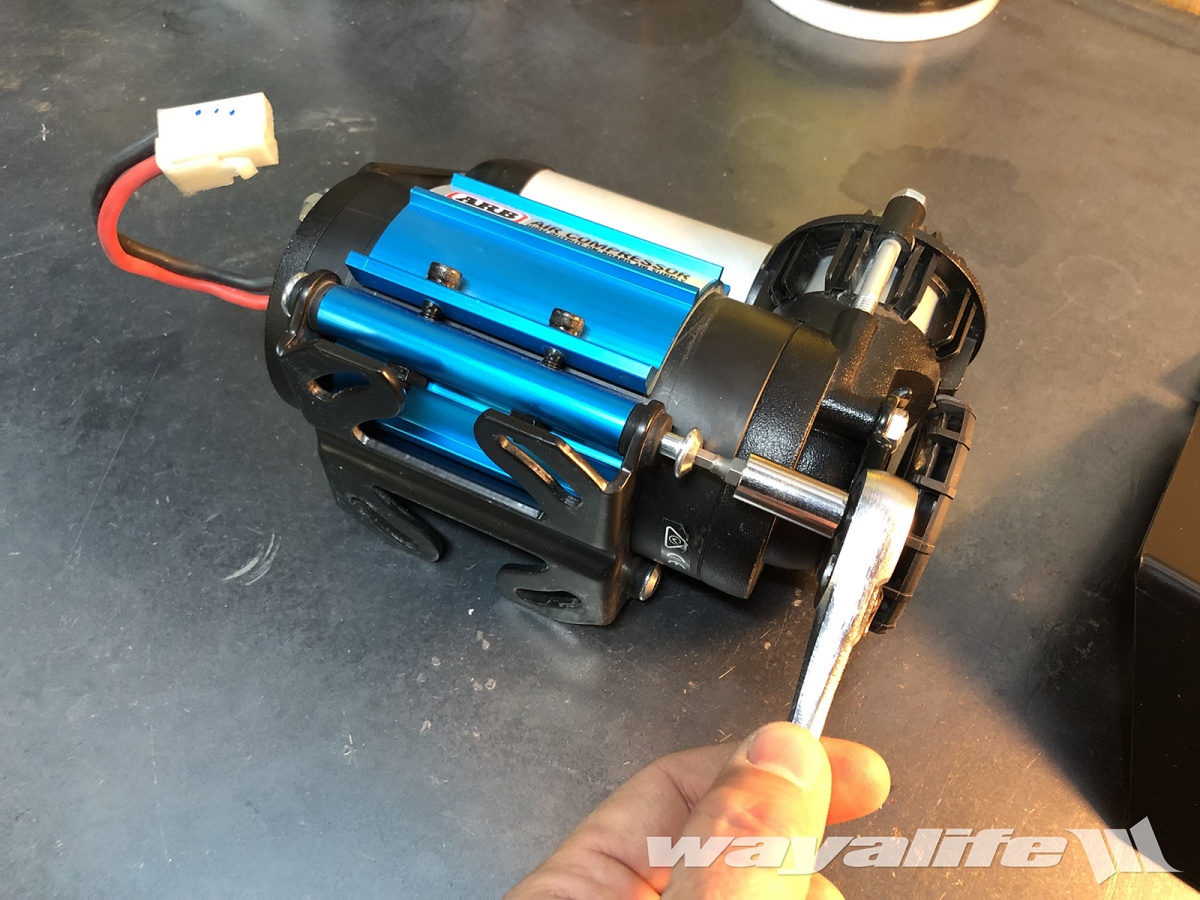

13. Lay your ARB Air Compressor on its side and then, use a 4mm allen bit or wrench to remove the 2 pins securing it to the base.

14. With the 2 pins removed from just the one side, rotate the ARB Air Compressor open to expose the mounting base.

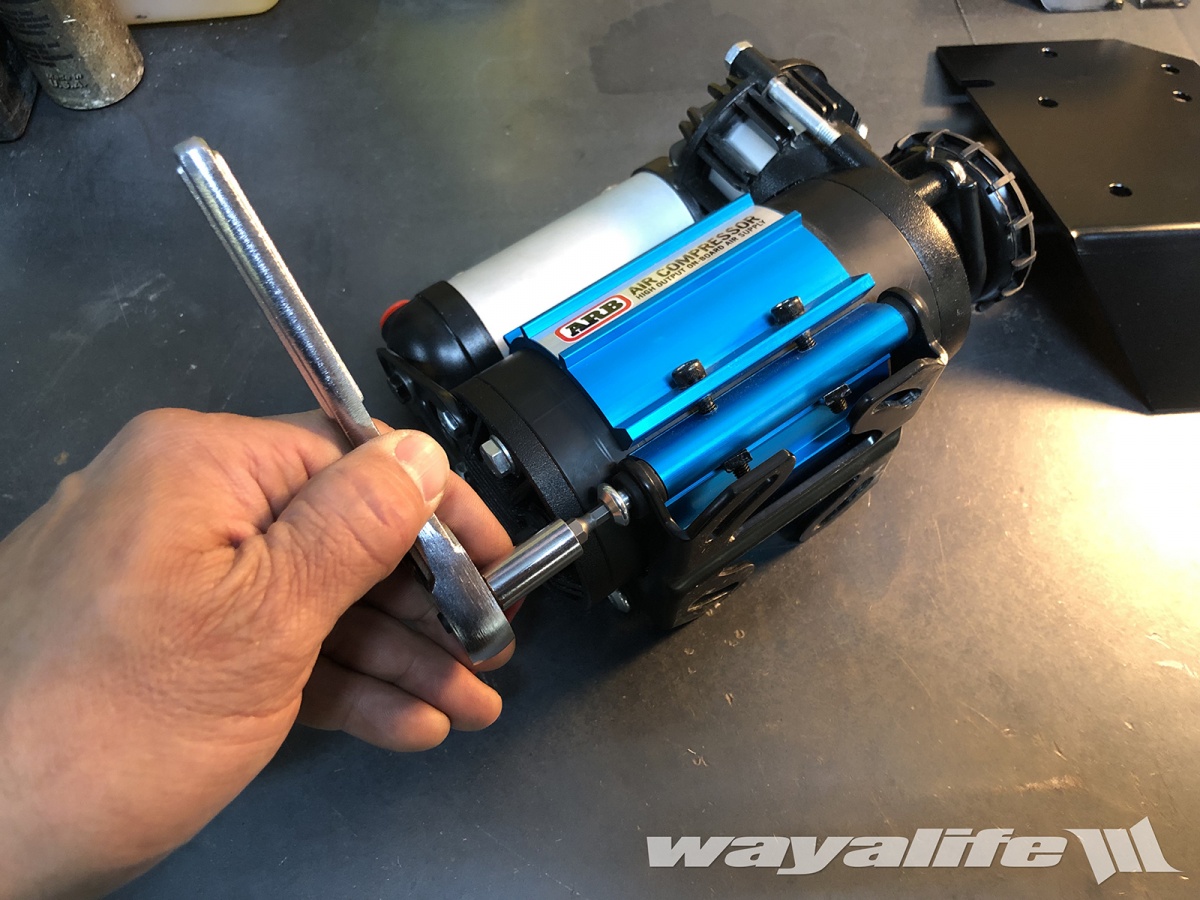

15. Take one of the 1/4"-20x1/2" bolts, slip it through the back side of the ACM and hold it in place with your finger.

16. With the filter end of the ARB Air Compressor pointing up, place the mounting base on top of the ACM and with the 1/4"-20x1/2" bolt passing through the upper hole closest to the hinge. Then, secure it in place with a 1/4"-20 serrated flange nut. Just tighten it finger tight for now.

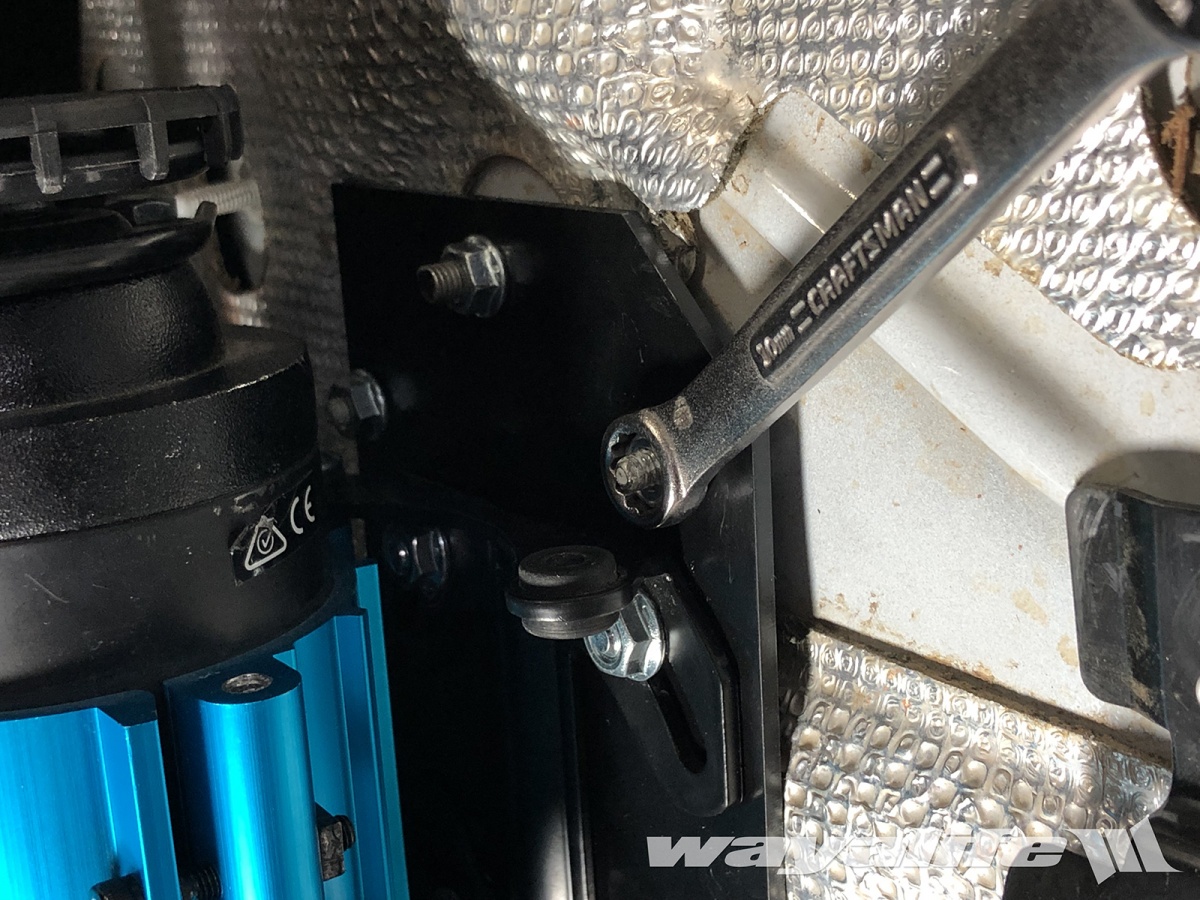

17. Proceed to secure the ARB Air Compressor mounting base to the ACM by installing the 3 remaining 1/4"-20x1/2" bolts and serrated flange nuts.

18. Using a 7/16" socket, tighten up all 4 bolts. The serrated flange nuts should make it unnecessary to use a wrench on the opposite side.

19. Rotate the ARB Air Compressor back to the closed position. Then, use a 4mm allen bit or wrench to loosen the 2 clamp bolts just below the label and just a bit so that the barrel of the compressor can be shifted to either side with some effort.

20. Place the ACM onto the 3 firewall studs that you placed spacers on and make sure that the lower slot slips over the stud on the angled bottom side of the wall. NOTE: The upper middle stud may make contact with the barrel of your ARB Air Compressor and it may need to be shifted down in the clamp a bit in order to make it clear. If you would like it to sit higher, you will need to cut the un-threaded tip of the middle stud using a Dremel or the like with a cutoff wheel.

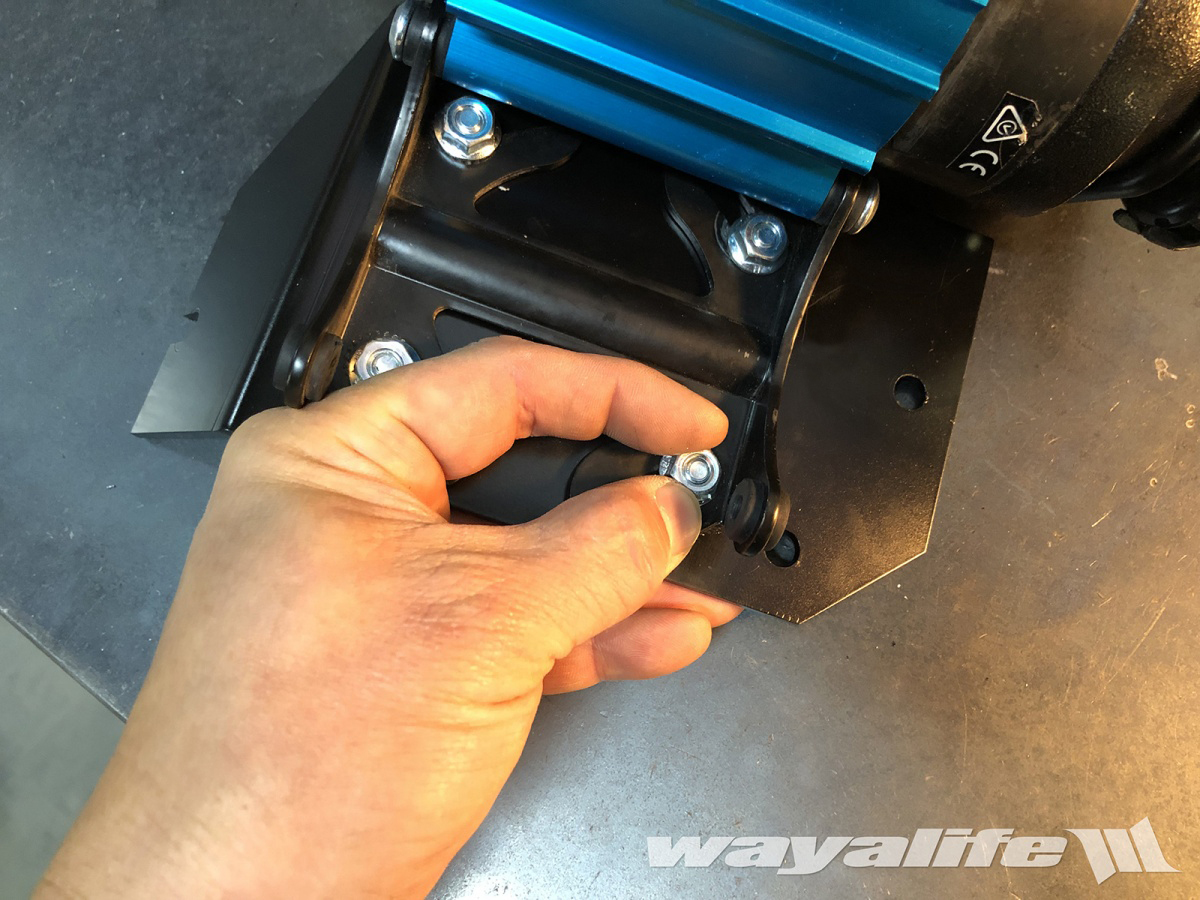

21. Rotate the ARB Air Compressor open to give you more access to the firewall studs.

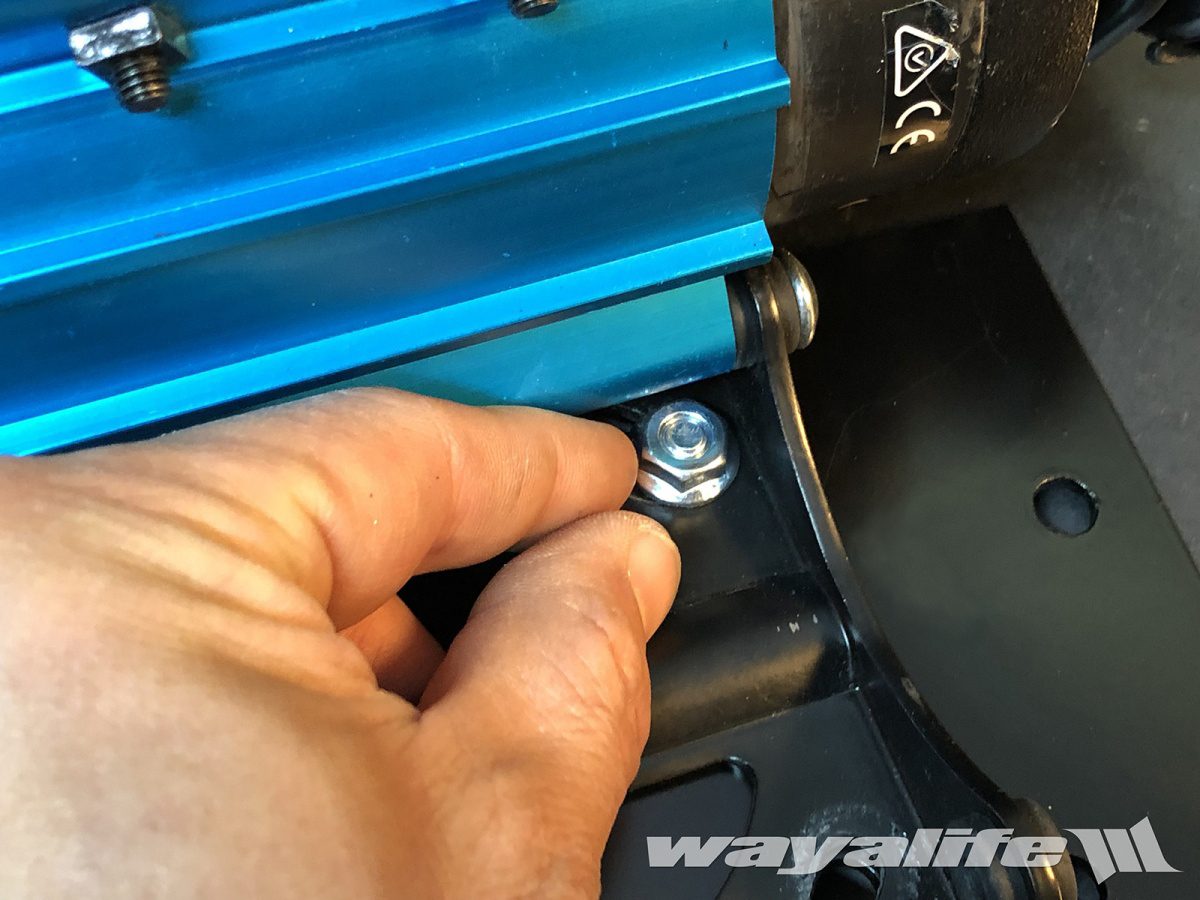

22. Using a 10mm wrench, secure the ACM to the studs on the firewall of your JL Wrangler or JT Gladiator using the M6x1.0 serrated flange nuts provided.

NOTE: You will need to place the M6 washer on the bottom stud before installing the M6x1.0 serrated flange nut.

23. Rotate the ARB Air Compressor closed and then, use a 10mm socket on a ratchet to tighten the nut attached to the stud closest to the engine.

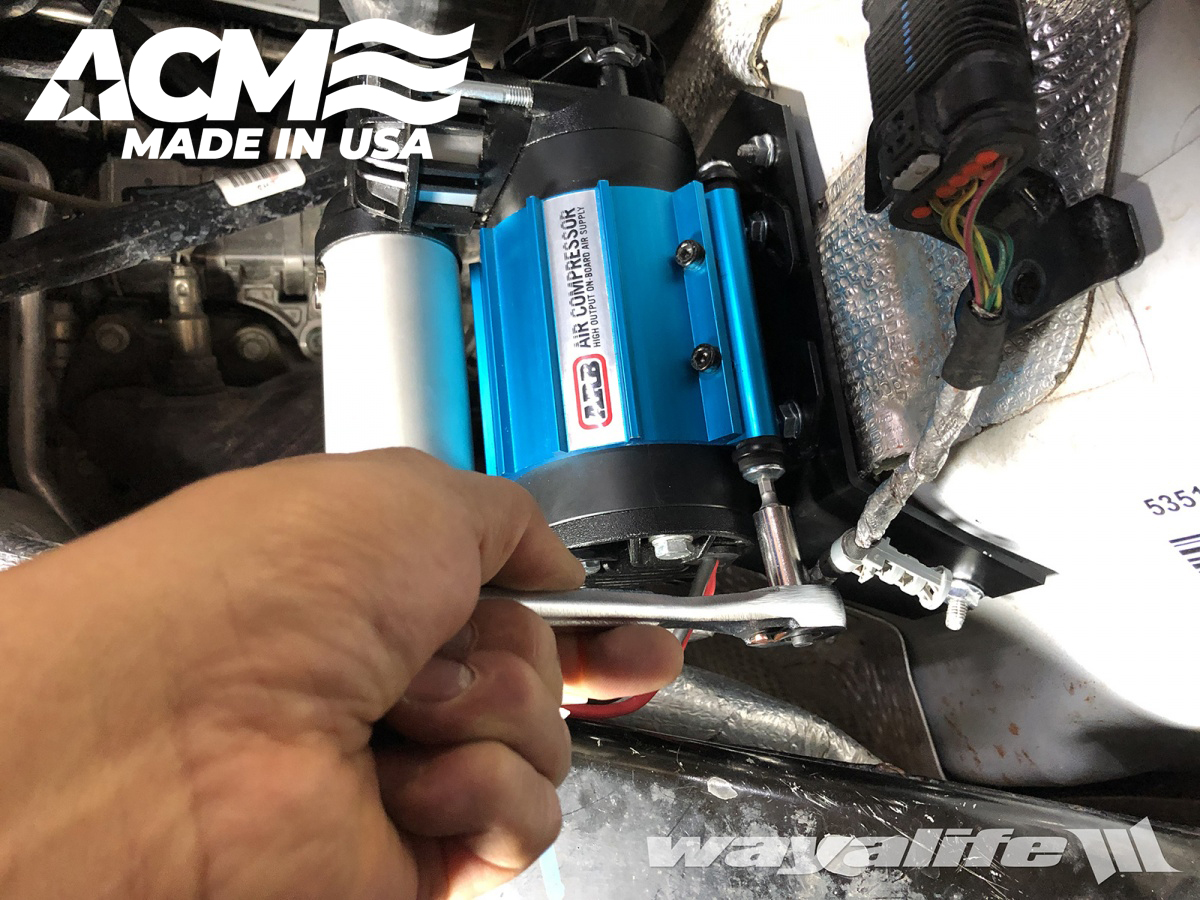

24. Reinstall the ARB Air Compressor mounting base pins and secure them in place using a 4mm allen bit or wrench.

25. Verify the position you want your ARB Air Compressor to sit and then tighten the 2 clamp bolts using a 4mm allen bit or wrench.

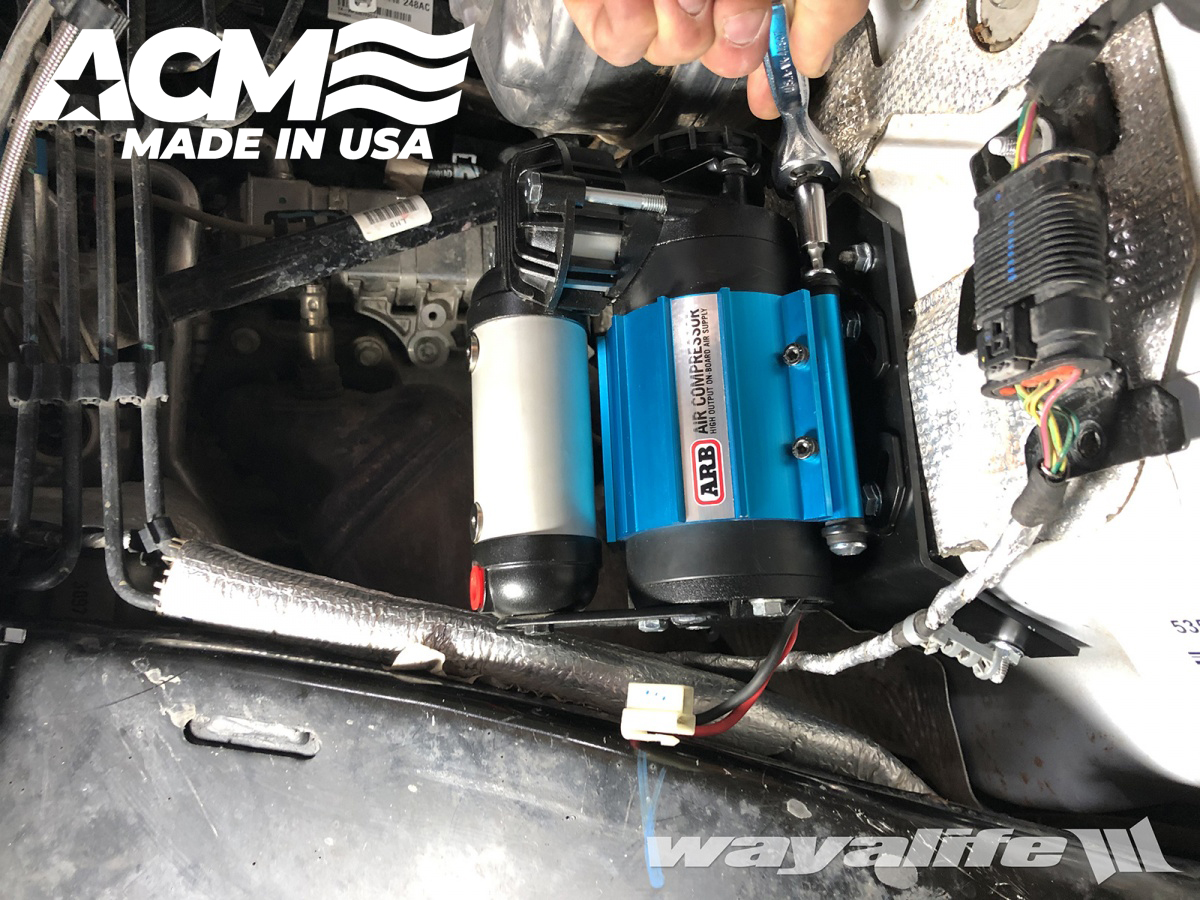

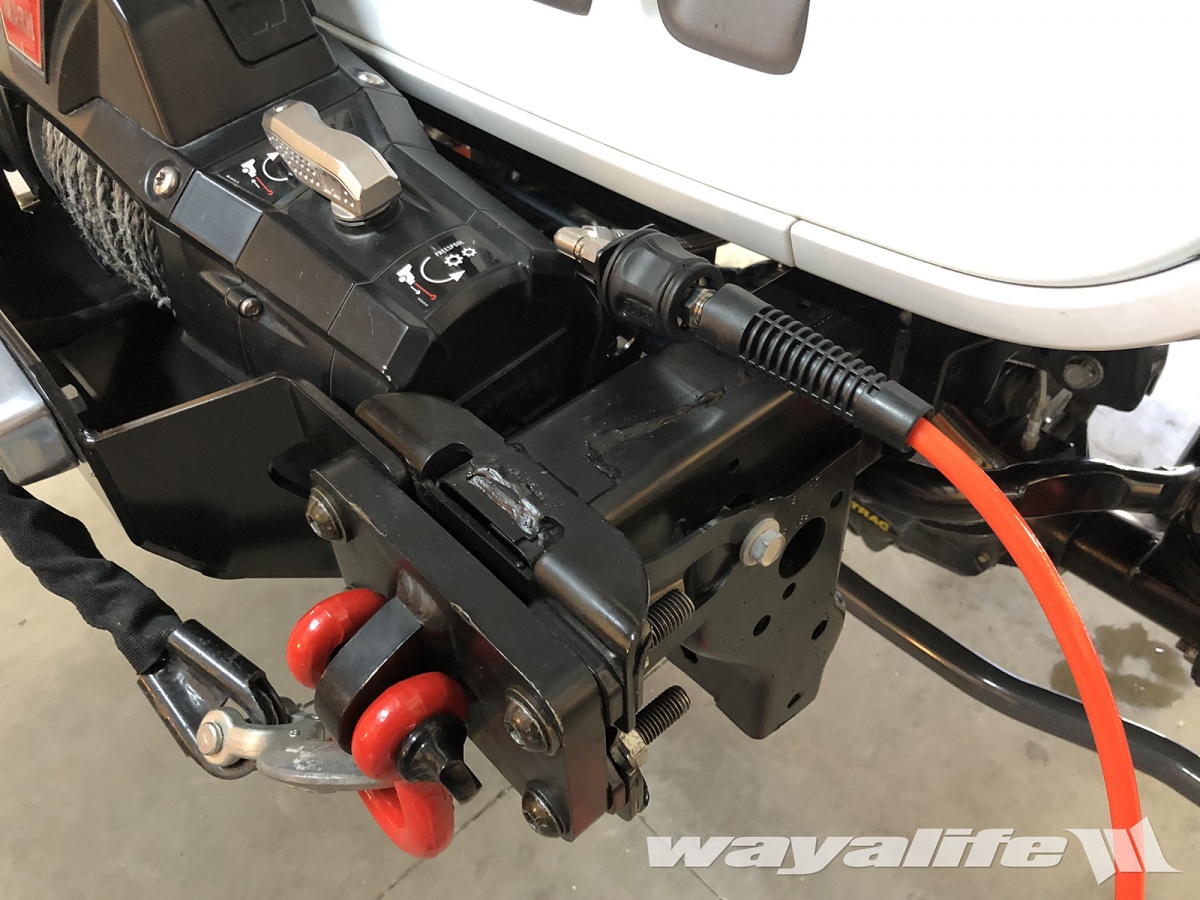

Finally, here's what your ARB Air Compressor bolted up to a WAYALIFE ACM and mounted to the firewall of your JL Wrangler or JT Gladiator should look like. From here, all you need to do is get it wired up and plumbed for air.

Wiring Up & Plumbing the ARB Air Compressor

There are a few different ways to get your ARB Air Compressor wired up and plumbed for air but for those of you who are interested, the following instructions will show you how I did things. It should be noted that I do have a Dyantrac ProRock 44 with an ARB Air Locker and the final photos do show the solenoid attached to the ARB Air Compressor. However, for the purposes of this write-up, I did not include instructions for it being installed being that most people will not be running an air locker.

1. Remove the red plug located on the bottom of the air cylinder.

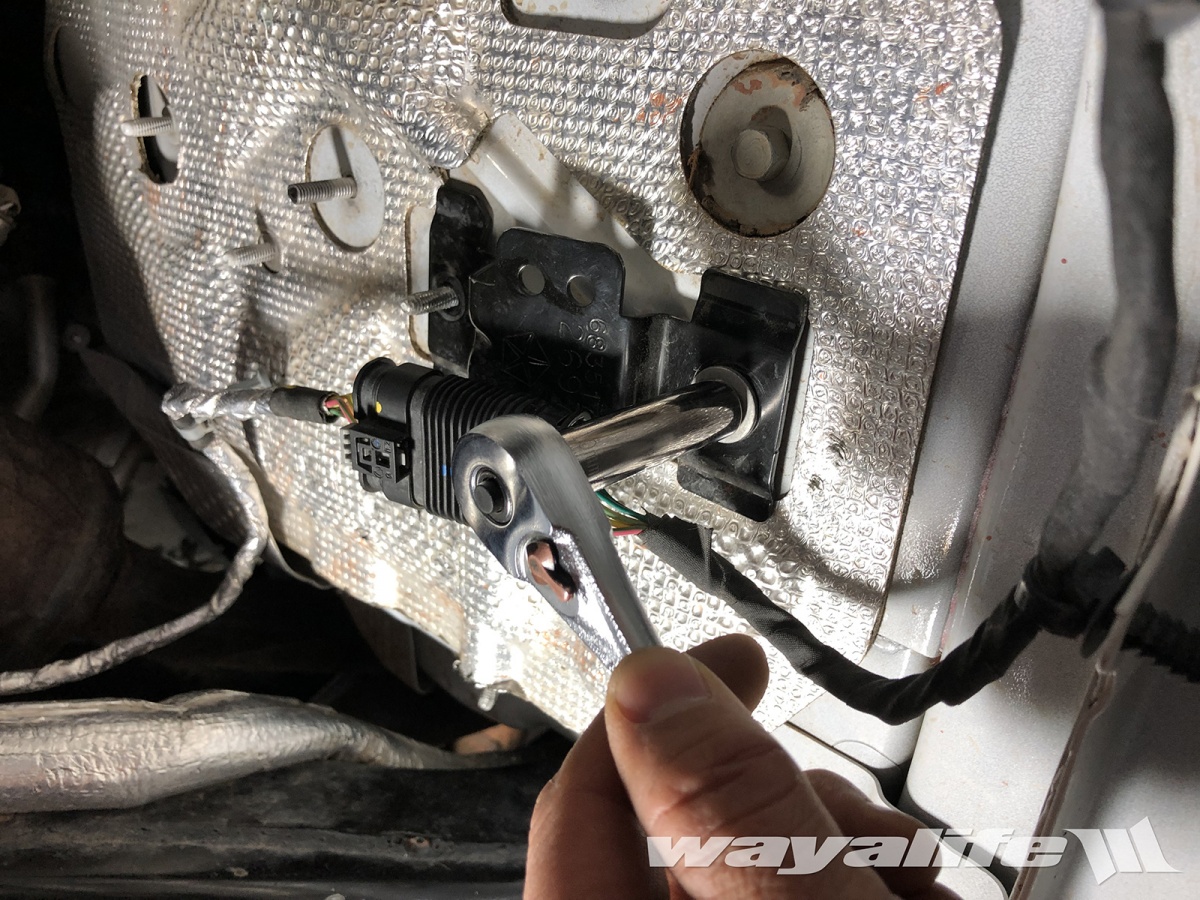

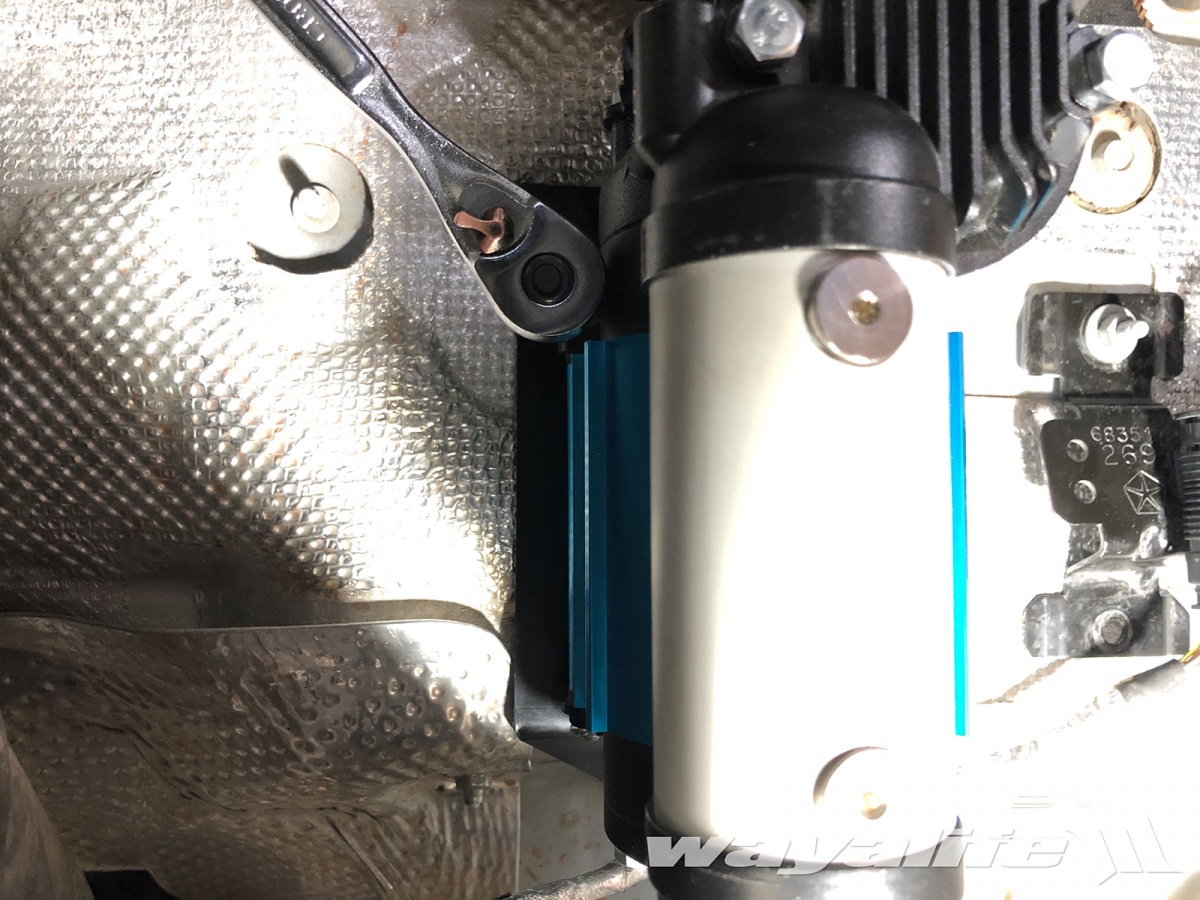

2. If needed, you can use a 10mm wrench to loose the following bolt on the bottom of the air cylinder bracket and that will allow you to rotate both the black end and the silver cylinder as needed.

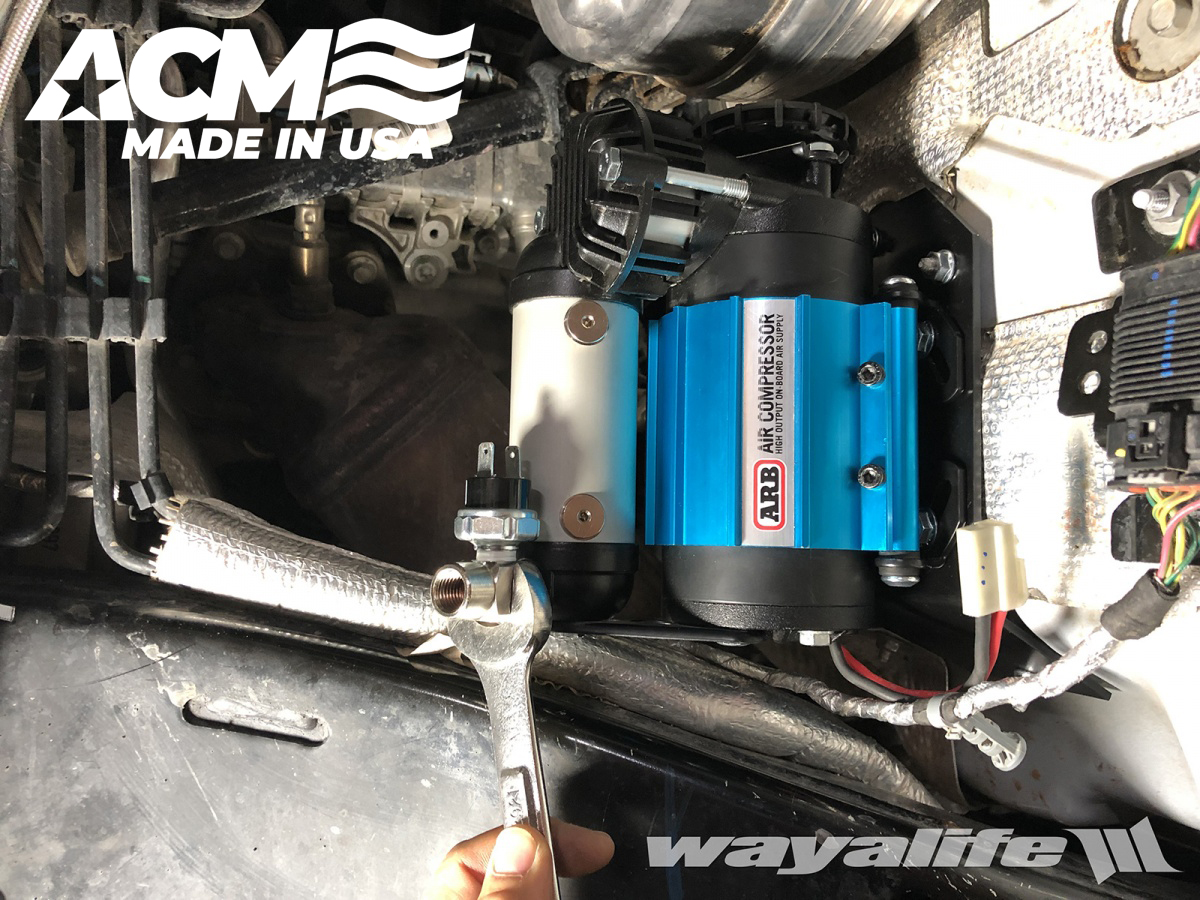

3. Apply some teflon tape to the threads of the air chuck/pressure sensor manifold.

4. Use a 19mm wrench to partially install the air chuck/pressure sensor manifold onto the ARB Air Compressor.

5. Apply teflon tape to the threads of the pressure sensor.

6. Use a crescent wrench to secure the pressure sensor to the side of the manifold.

7. Using a 19mm wrench, set the manifold to the final position you want it to sit in.

8. Apply teflon tape to the threads of the air chuck.

9. Use a 19mm wrench to secure the air chuck onto the front of the manifold.

NOTE: If you are installing a remote air chuck, you will want to install the fitting for it in place of the air chuck now.

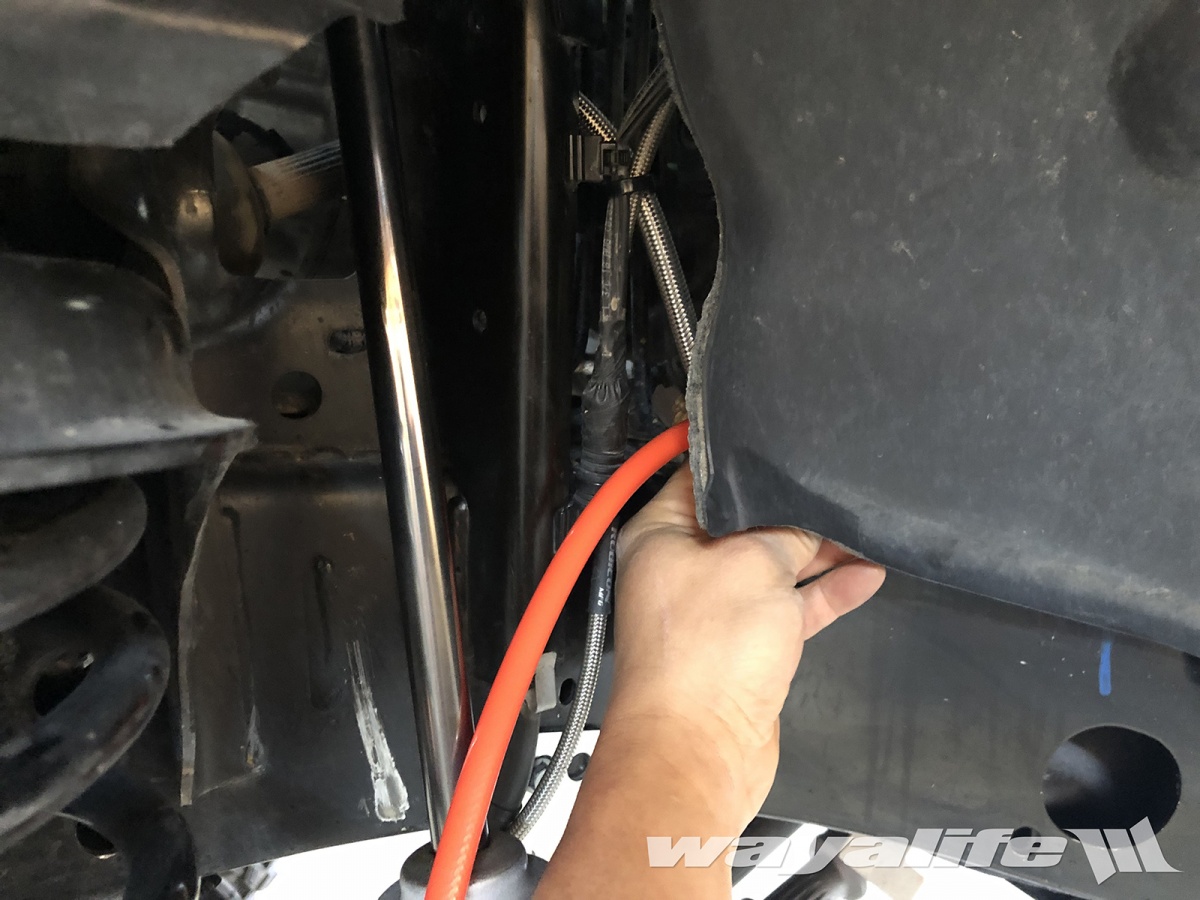

10. Drape the ARB wiring harness along the top edge of your JL Wrangler or JT Gladiator's firewall and zip tie it in place.

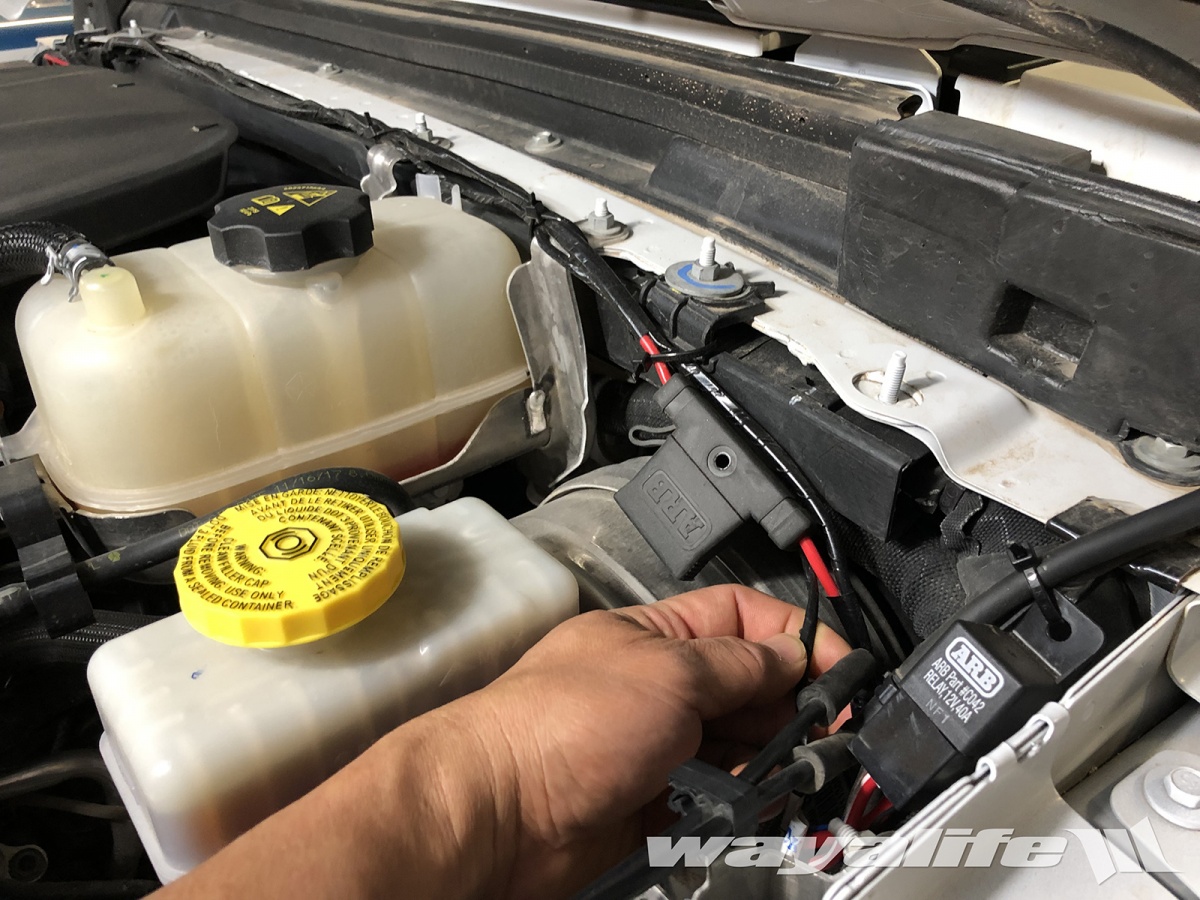

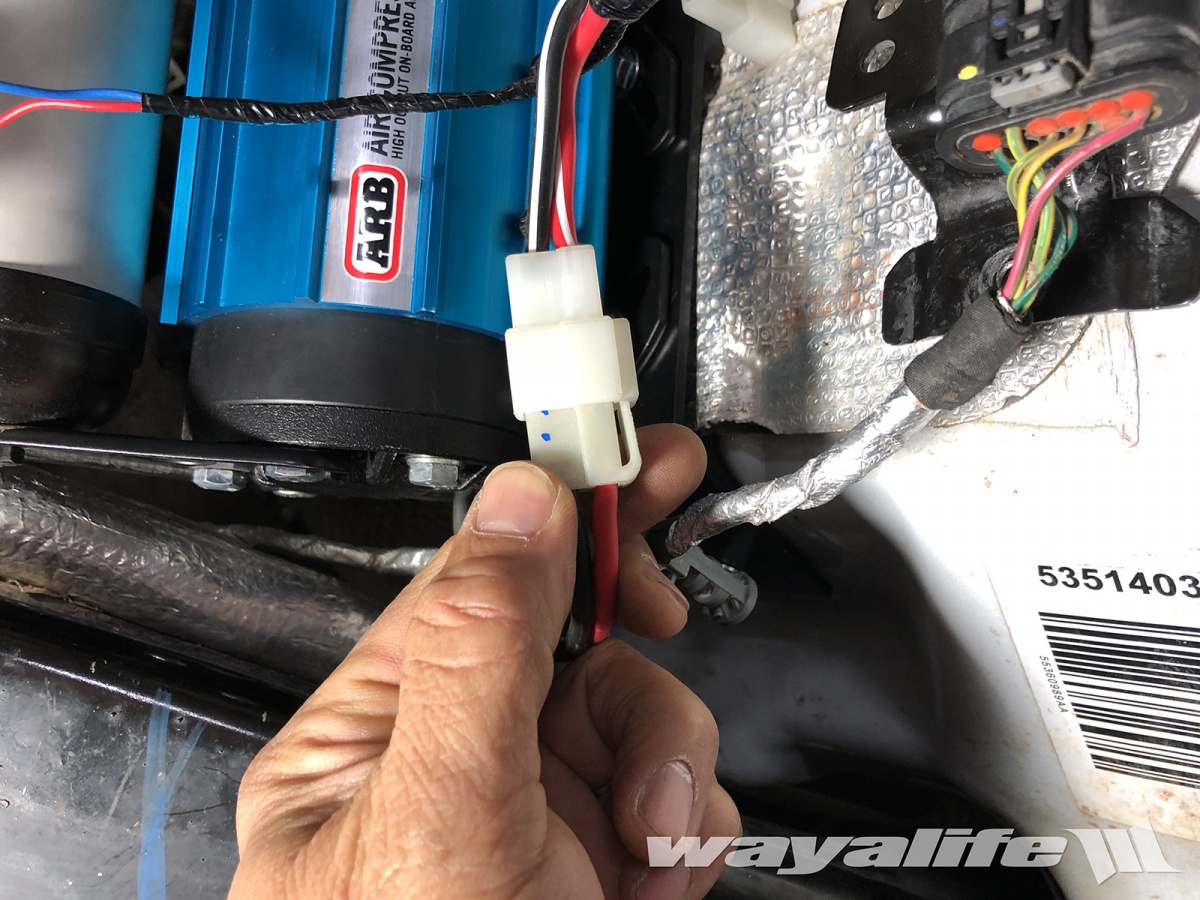

11. Plug in the red and black wires with the white stripes into the solid red and black wires attached to the ARB Air compressor.

12. Plug in the red and blue wires onto the pressure sensor terminals.

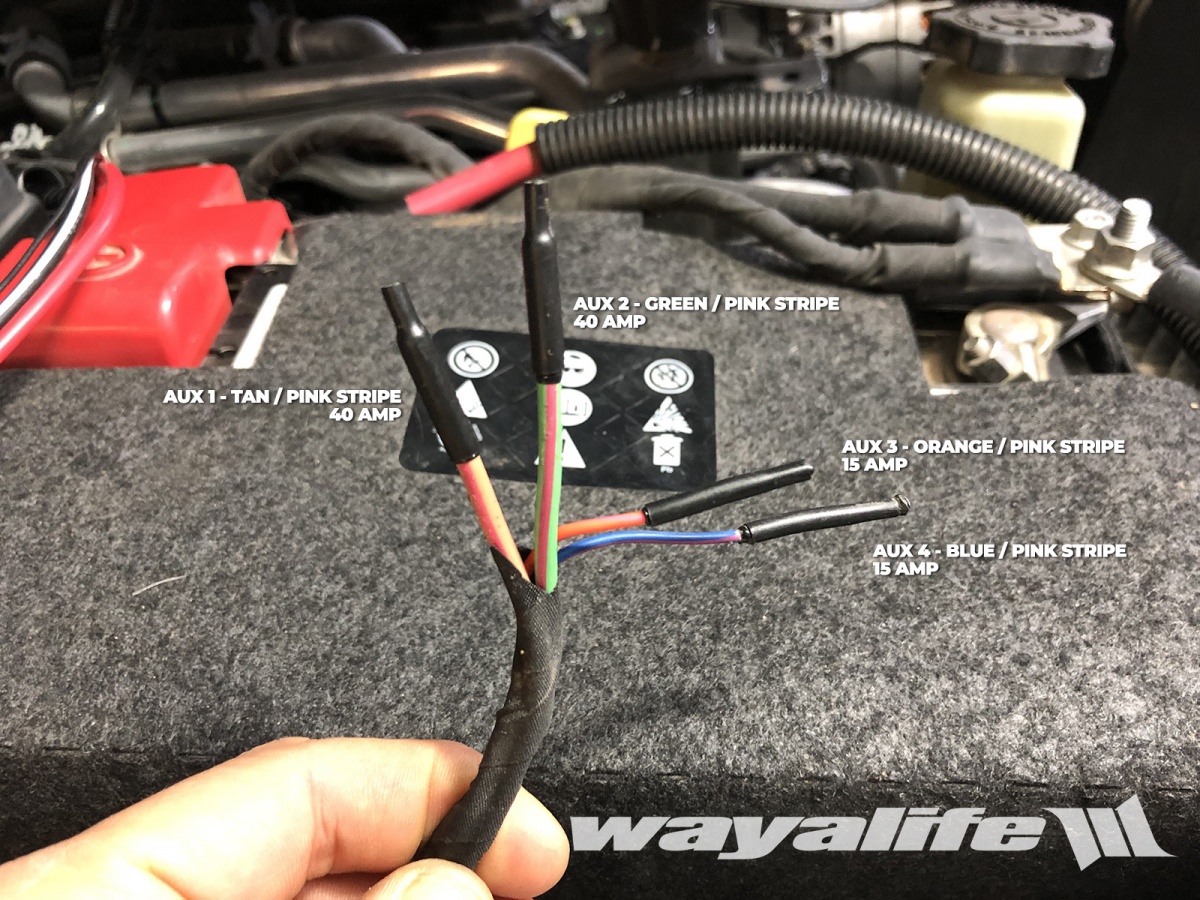

13. If you purchased your JL Wrangler or JT Gladiator with AUX switches, identify which switch you would like to operate your ARB Air Compressor. For my purposes, I decided to make AUX 1 = Air Compressor and AUX 2 = Front Locker.

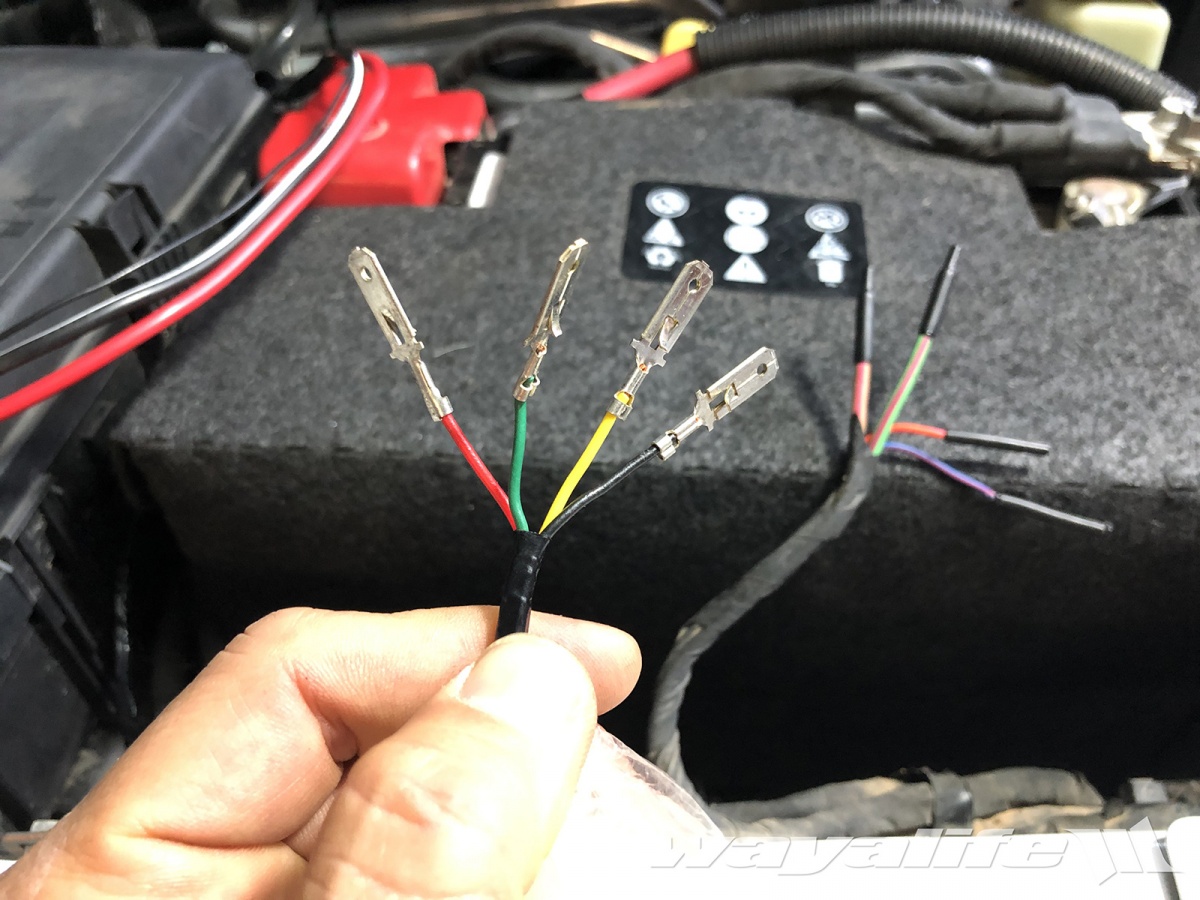

14. Separate the wiring on your ARB Air Compressor loom: RED = Compressor / YELLOW = Locker Switch #1 (front locker for our purposes) / GREEN = Locker Switch #2 / BLACK = Ground (not needed).

15. Use wire strippers to cut off the insulator.

16. For my purposes, I attached female blade terminals to the factory wires.

17. Again, for my purposes, I installed the plug housing that came with the ARB wiring and then connected the factory TAN/PINK STRIPE wire (#1 AUX) to the ARB RED wire and the factory ORANGE/ PINK wire (#3 AUX) to the ARB YELLOW wire.

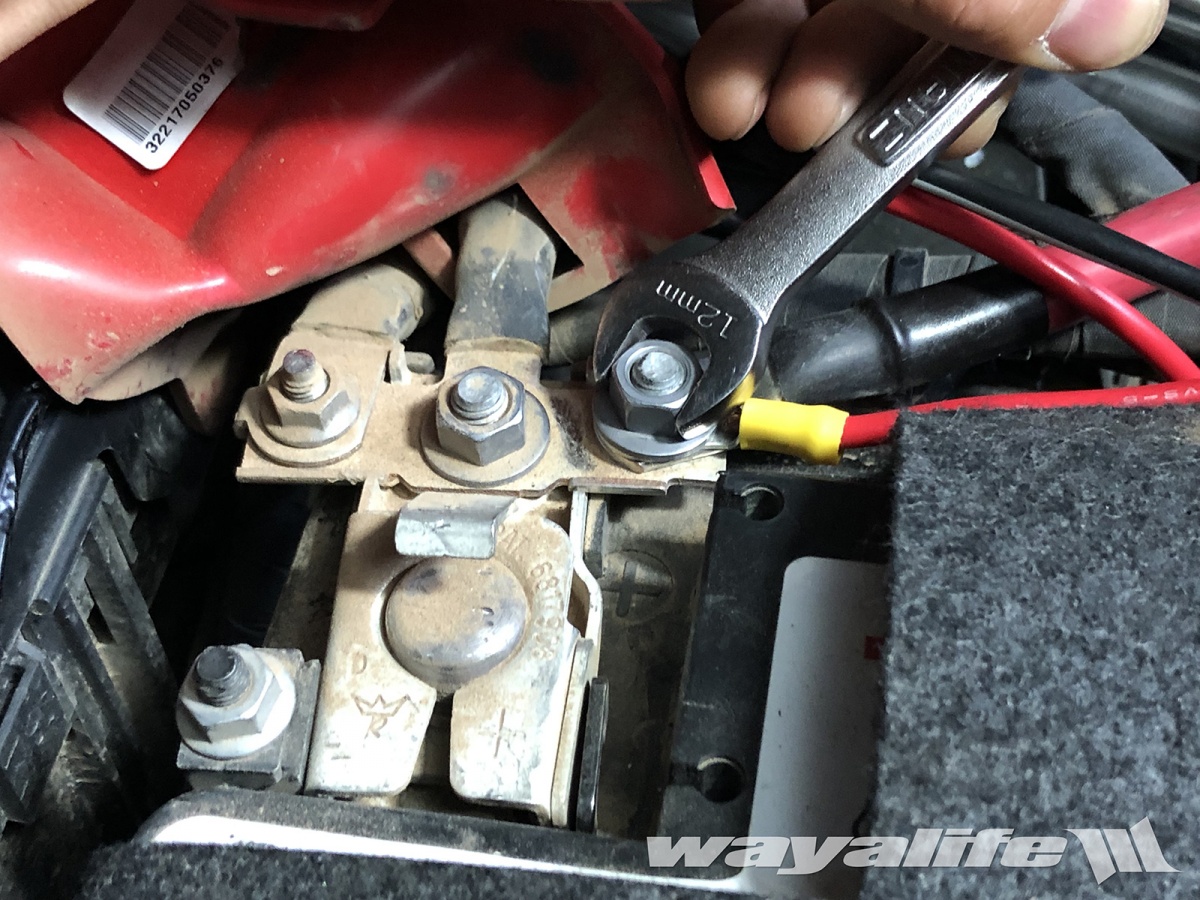

18. Using a 12mm wrench, attach the ARB RED power lead to the positive AUX terminal on your battery.

19. Using a 13mm wrench, attach the ARB BLACK ground lead to the negative AUX terminal on your battery.

20. Inside your JL Wrangler or JT Gladiator, push the AUX 1 button to test your ARB Air Compressor. This should go on with or without a the ignition set to the run position. If you got everything wired up correctly, you should hear the compressor charge up and stop. If after several seconds or even a minute later, the compressor starts to charge up again, you most likely have a leak somewhere. Use some soapy water and apply it to all the fittings to help identify where it is and fix it.

Wrapping Things Up

1. Once you've verified that everything works and you have no leaks, you can begin the process of reinstalling your driver side fender. Of course, if you ended up breaking any fender clips, now would be the time to replace them. If you still have pieces attached to the body, you can use needle nose pliers to squeeze the clips from behind the body panel and push them through.

2. With all the clips in place, hold up your fender so to the point where you can reconnect the wiring and lock it in.

3. Then, slide the fender onto the metal brackets, line up the fender clips to the holes on the body and simply push it in till they all click.

4. Re-install the 4 factory fender liner bolts and secure them in place with a 10mm socket and re-install the trim push tab.

5. If you removed your wheel to gain more access, reinstall it now and make sure to tighten your lug nuts to 130 ft. lbs. of torque. Otherwise, that's all there is to it.

Using the ARB Air Compressor

Now that you have an ARB High Output Air Compressor mounted under the hood, you can air up the tires on your Jeep JL Wrangler or JT Gladiator anytime and anywhere. All you have to do is connect your air hose, turn on the compressor and go. If you just installed the air chuck on the manifold, you can access it simply by reaching in behind the fender liner just behind the shock tower.

Of course, if you want to make things even easier, you can always install an air chuck in a remote location like I did.

Please let me know if you have any questions.