Project “Get The Flex Back” started. Since adding my DIY budget boost, I knew that shock extensions would be needed to regain full axel droop and maximize total flex.

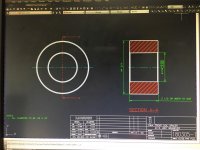

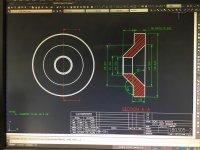

I started with taking some basic measurements and spent some time designing some extension brackets for the front shocks. Once I had the concept on paper, I found a 2” x 2” piece of cold rolled steel and cut 2pcs to 3 5/8” long:

After some layout and milling, it was time use a round over bit to make a nice radius to keep from wearing the brake line:

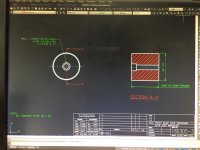

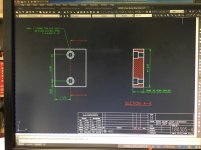

At the Bridgeport, I drilled the mounting holes 2” apart which should produce 2” more shock travel:

Back at the heavier knee mill, I continued with machining the features of the bracket:

The last step was to shape a radius at the top of the bracket at the belt sander:

At home, the brackets were installed and tested:

With the sway links disco’ed and body lifted until the front tire just lifted off the ground, I measured 2 3/8” more droop:

I’m pleased with how the brackets turned out! A little paint is all they need and then I will re-measure total flex with the forklifts again. I also need to investigate whether rear shock extensions would be beneficial.