theNomad

New member

After all the work I figured I'd share my adventure in plastic welding.

When I bought my Jeep it had a few punched in dents in the plastic bumper. I wanted to fix this and also improve the look of the Jeep but didn't want to spend much money.

On Craigslist I came across a set of factory bumpers that were no longer needed and the gentleman offered them to me for free.

Sweet! Project time!

My goals were:

1) replace the damaged plastic bumper parts

2) give it a stubby bumper look

3) maintain a quality looking result

4) do it as cheaply as possible

I'm far from the first to do this but figured I'd chronicle my efforts once again. I chose to try the plastic welding method I'd seen others use (while not investing in the tools, because I like a challenge ha!)

Tools used:

Heat Gun

Soldering Iron (cheapo)

Dremel

Razor knife

Tape measure

I took the bumper and carefully measured the areas to cut out. I wanted to keep the bumper bolt tab and fold the bumper back on itself to form the endcap.

I used a Dremel to cut it and it was fairly messy. I began to use a razor later on after warming it with a heat gun first. That ended up being a better solution. Just go slow and be careful.

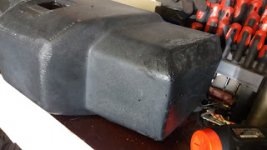

After cutting the unneeded materials I got it soft with the heat gun and bent it back into a clean fold.

The process of matching up the edges and welding them together was much more tedious and while I tried to be as careful as I could be it still got a bit messy. I regret not buying the plastic weld kit... just a bit.

All bonded and feels strong but still messy. I sanded it down with 80 grit sandpaper to smooth out the chunky spots. I'll get some plastic epoxy to reinforce the backside and I sprayed it with bedliner to hide imperfections.

Today I got out before the temps hit 116 degrees again and took off the factory bumper.

I chopped about 4 inches off both sides of the steel bumper reinforcement. I transferred the fogs and the painted center section to the stubby cover.

I also trimmed a section of the air dam undertray as I am reinstalling it.

The project wasn't "easy" but it was cheap! (Under $20 for the paint and primer)

When I bought my Jeep it had a few punched in dents in the plastic bumper. I wanted to fix this and also improve the look of the Jeep but didn't want to spend much money.

On Craigslist I came across a set of factory bumpers that were no longer needed and the gentleman offered them to me for free.

Sweet! Project time!

My goals were:

1) replace the damaged plastic bumper parts

2) give it a stubby bumper look

3) maintain a quality looking result

4) do it as cheaply as possible

I'm far from the first to do this but figured I'd chronicle my efforts once again. I chose to try the plastic welding method I'd seen others use (while not investing in the tools, because I like a challenge ha!)

Tools used:

Heat Gun

Soldering Iron (cheapo)

Dremel

Razor knife

Tape measure

I took the bumper and carefully measured the areas to cut out. I wanted to keep the bumper bolt tab and fold the bumper back on itself to form the endcap.

I used a Dremel to cut it and it was fairly messy. I began to use a razor later on after warming it with a heat gun first. That ended up being a better solution. Just go slow and be careful.

After cutting the unneeded materials I got it soft with the heat gun and bent it back into a clean fold.

The process of matching up the edges and welding them together was much more tedious and while I tried to be as careful as I could be it still got a bit messy. I regret not buying the plastic weld kit... just a bit.

All bonded and feels strong but still messy. I sanded it down with 80 grit sandpaper to smooth out the chunky spots. I'll get some plastic epoxy to reinforce the backside and I sprayed it with bedliner to hide imperfections.

Today I got out before the temps hit 116 degrees again and took off the factory bumper.

I chopped about 4 inches off both sides of the steel bumper reinforcement. I transferred the fogs and the painted center section to the stubby cover.

I also trimmed a section of the air dam undertray as I am reinstalling it.

The project wasn't "easy" but it was cheap! (Under $20 for the paint and primer)

Last edited: