ESSAYONS12B

New member

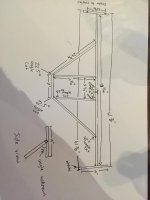

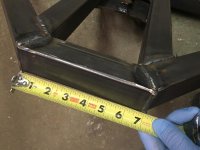

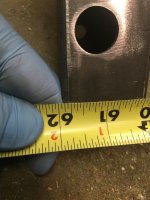

Finally decided to fab up a tire carrier last weekend. I wanted to get the tire off the tailgate but also compatible with an aftermarket soft top. I decided on this setup. I used 2" square tube steel and scavenged parts from a old fabtech pickup bed tire carrier I had laying around. It worked out better than expected it doesn't touch the seats and it's elevated off the cargo floor and still leaves some cargo area underneath and behind the seats. Also not visible but has threaded studs on underside for mounting my Hi Lift Jack.

Last edited: